You are here

Good glazing properties are important because they control the amount of daylight, quality of light, and amount of solar heat gain let into the building, along with other factors. They very much determine the thermal comfort and visual comfort of a space.

|

|

Certifying window thermal performance |

Fenestration is any opening in the building envelope. When that opening is covered with a translucent or transparent surface (like windows or skylights), that’s called glazing.

Three of the most important properties of the materials, coatings, and constructions that make up windows, skylights, translucent panels, or other products used to let sunlight into a building include

1. Thermal conductance (U-value)

2. Solar Heat Gain Coefficient (SHGC)

3. Visible Light Transmittance (VT)

Appropriate values for glazing properties vary by climate, size, and placement of the aperture. There is no one best kind of glazing to use. It's not unusual for a single building to have three, four, or even five different kinds of glazing for apertures in different sides and at different heights on a building.

|

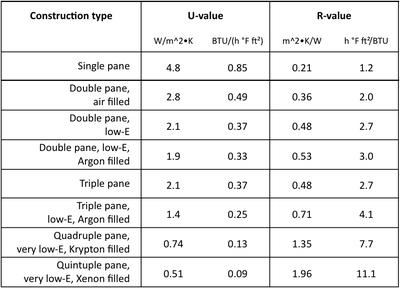

| U-values for various glazing constructions |

Thermal conductance (U-factor)

As with opaque envelope components, sensible heat flow due to temperature differences through windows and skylights is a function of the U-factor (See Heat Energy Flows). It measures how well glazing insulates or rather, how poorly glazing insulates.

U-factors measure thermal conductivity, the rate of heat transfer per unit area, per unit temperature difference from the hotter side to the colder side. This is W/(m²K) in SI units, BTU/(h°F ft²) in Imperial unitsIt is important to know which units you're working in. R-values are 1 / U-factor.

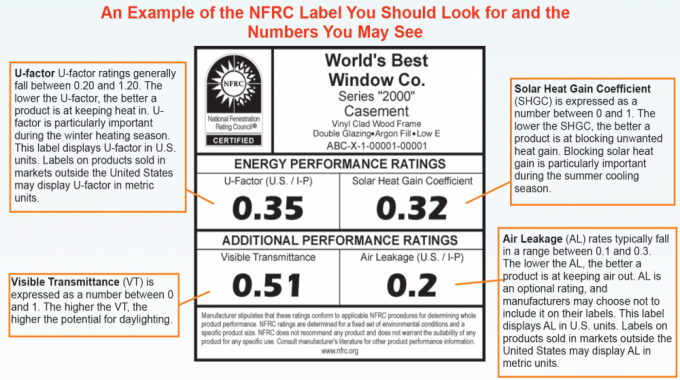

U-factors are either measured for the glazing only (“center of glass”) or for the entire window assembly (including framing and spacers). There are significant differences in heat flow rates between the center-of-glass, edge-of-glass, and frame portions of a unit, so the U-Factor for the entire window assembly is the value most-often referenced. The NFRC (National Fenestration Rating Council) is a trusted source for this information.

The size of the air gap between glazings, the coatings on the glazings, the gas fill between glazings, and the frame construction all influence the U-factor.

In cold climates, a low U-value is usually the most important window property and a rule of thumb is to look for windows with a U-value of 0.35 or less (Imperial units). In warmer climates, low U-values are often less important than the Solar Heat Gain Coefficient because gains from direct solar radiation are more important than conduction through the window.

|

| Heat transmission and radiation from a window |

Solar Heat Gain Coefficient (SHGC)

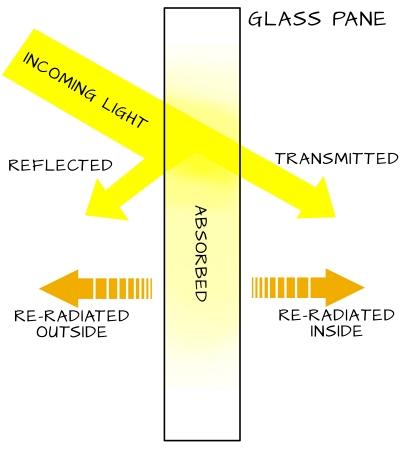

Solar Heat Gain Coefficient (SHGC) measures how much of the incoming heat from sunlight gets transmitted into the building, versus how much is reflected away. Heat from the sun is long-wave radiation (infrared and other non-visible light).

This thermal property is also generally based upon the performance of the entire glazing unit, not just the glass. The SHGC depends upon the type of glass and the number of panes, as well as tinting, reflective coatings, and shading by the window or skylight frame.

The SHGC is a dimensionless number between zero and one. SHGC can theoretically range from 0 to 1, with 1 representing no resistance (all of the heat from the incoming sunlight comes through) and 0 representing total resistance (none of the sun's heat reaches the inside). SHGC values for real products typically range from about 0.9 to 0.2.

Choosing the right SHGC depends on the size and placement of the apertures as well as climate and other design factors. The SHGC is especially important in hot sunny climates (where cooling is the dominant thermal issue), and you should generally use glazing with lower SHGC (below ~0.4). Buildings in cold climates should generally have higher SHGC to enable passive solar heating and to reduce heating loads.

The SHGC for ordinary uncoated, un-tinted glass can be .9, while values can be as low as .25 or even .15 for some specialized glazing units. In spectrally selective glazing, the SHGC can be independent of visible light transmission. The Light to Solar Gain ratio is used to measure the effectiveness of spectrally selective glazing and is visible light transmittance divided by solar heat gain coefficient.

Visible Light Transmittance (VT)

The point of windows is to let light pass through. The percentage of visible light that passes through a window or other glazing unit is called the Visible Light Transmittance (VT). Also known as Tvis, VLT and LT. An opaque wall would have a VT of 0%, while an empty opening would have 100%; many un-tinted glass and plastic materials have a VT of 90% or more. VT does not measure shorter-wavelength light like UV or longer-wavelength light like infrared only visible light.

More light is often not better, as it can cause glare and overheating. Tints, frits, and coatings can be chosen to produce any VT; common values are often 30 - 80%.

VT is influenced by the color of the glass (clear glass has the highest VT) as well as by coatings and the number of glazings.

VT may be expressed relative to the glass portion of a glazing unit only or relative to the glass and frame. The appropriate expression will depend upon the nature of an analysis; in any case, non-comparable values should not be compared. All NFRC-certified VT values are directly comparable.

|

LCD films are switched on or off to provide clear or diffusing coatings. Demonstration from the Pacific Energy Center. |

Adaptive Properties

Some advanced glazing systems can change their visible light transmittance, solar heat gain coefficient, and other properties.

- Liquid crystal windows change from clear to frosted or dark when a voltage is applied by a control system, improving their privacy but not changing their solar heat gain.

- Thermochromic coatings turn from clear to dark at high temperatures (generally when struck by direct sunlight), reducing their VT and SHGC.

- Photochromic coatings turn from clear to dark when struck by light; many sunglasses use this feature.

- Electrochromic coatings change from clear to dark when a voltage is applied by a control system, also reducing their VT and SHGC.

- For additional information on adaptive properties, see Building Science Fundamentals.

Other Considerations

Some other significant variables to consider with windows or other apertures are infiltration rates, light distribution angles, condensation, and acoustics.

Infiltration is air leakage through the framing of a glazing unit. Tightening a unit can improve effective U-values by 10% or more. Standard leakage rates are .3 CFM/ft2 (0.0015 m/s) while tight units can be as low as .02 (0.0001) or even .01 CFM/ft2 (0.00005 m/s).

Light distribution angles are the direction that light is transmitted into the building. Ordinary windows let light travel straight through, while advanced glazing units may bounce the light to different angles, or spread it diffusely through the room. This is usually especially important for skylights.

Condensation can occur in glazing units when there is a large temperature difference from inside to outside. In addition to being unsightly, this can cause mold and mildew, which is detrimental to indoor air quality. Good glazing units control condensation.

Acoustic damping is valuable, since glazing generally transmits more sound than walls. Noise can be problematic for buildings in noisy locations. Some glazing units have better acoustic damping than others, particularly multi-pane constructions that use different glass thicknesses and layers of different material in their framing.

Links and References

- A deep resource on understanding glazing properties.

- From the National Fenestration Rating Council