You are here

Thermal insulation is a material that blocks or slows the flow of heat through the building envelope. Insulation is vital to most green building design because it allows spaces to retain what heat they have, while avoid gaining excess heat from outside.

It’s important to understand Heat Energy Flows in a building to understand insulation.Insulation primarily is designed to prevent heat transfer from conduction and radiation.

Resistance to conduction is measured by R-value (high thermal resistance = high R-value); Resistance to radiative heat transfer is measured by emissivity (high resistance = low emissivity and high reflectance). Conduction is the dominant factor when materials are touching each other; when there is an air gap between materials, radiation becomes important. Convection usually only becomes an issue when significant air pockets are involved.

Materials used for insulation fall into two broad categories:

(1) Fibrous or cellular products – These resist conduction and can be either inorganic (such as glass, rock wool, slag wool, perlite, or vermiculite) or organic ( such as cotton, synthetic fibers, cork, foamed rubber, or polystyrene).

(2) Metallic or metalized organic reflective membranes - These block radiation heat transfer and must face an air space to be effective.

R-values and Insulation (Conduction)

Below is a table of R-values for some common building products. For a more extensive list, see Archtoolbox.

| Material, 1" (2.5cm) thickness | m2•K/W | ft2•°F•h/BTU |

| Vacuum insulated panel | 5.28 - 8.8 | R-30 - R-50 |

| Polyisocyanurate spray foam | 0.76 - 1.46 | R-4.3 - R-8.3 |

| Polyurethane rigid panel | 0.97 - 1.2 | R-5.5 - R-6.8 |

| Closed-cell polyurethane spray foam | 0.97 - 1.14 | R-5.5 - R-6.5 |

| Extruded polystyrene (XPS), low-density | 0.63 - 0.82 | R-3.6 - R-4.7 |

| Expanded polystyrene (EPS) high-density | 0.65 - 0.7 | R-3.85 - R-4.2 |

| Air-entrained concrete | 0.69 | R-3.90 |

| Fiberglass batts | 0.55 - 0.76 | R-3.1 - R-4.3 |

| Cotton batts (Blue Jean insulation) | 0.65 | R-3.7 |

| Open-cell polyurethane spray foam | 0.63 | R-3.6 |

| Cardboard | 0.52 - 0.7 | R-3 - R-4 |

| Rock and slag wool batts | 0.52 - 0.68 | R-3 - R-3.85 |

| Cellulose wet-spray | 0.52 - 0.67 | R-3 - R-3.8 |

| Straw bale | 0.26 | R-1.45 |

| Softwood (most) | 0.25 | R-1.41 |

| Hardwood (most) | 0.12 | R-0.71 |

| Brick | 0.03 | R-0.2 |

| Glass | 0.025 | R-0.14 |

| Poured concrete | 0.014 | R-0.08 |

| Steel stud (source) | 5.3x10-4 | R-0.003 |

Table of R-values for 1" thickness of common building materials. From Wikipedia and Klepper, Hahn & Hyatt.

|

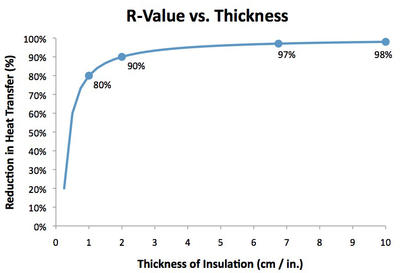

| Reduction in heat loss does not follow R-values linearly, but in an inverse logarithmic curve. |

Because R-values are 1 / conductance (U), doubling the thickness of insulation will not cut heat loss in half. Rather, there is an exponential decay of heat flow, where the difference between no insulation and one inch (or one cm) of a particular insulation may save 80% of heat loss, while going from one inch to two inches of that insulation saves an additional 9%, and going from 9 inches to ten inches only saves an additional 1%.

For more information on calculating the R-value of the envelope, see Total R-value and Thermal Bridging.

Low-Emissivity Insulation (Radiation)

|

| Low-emissivity insulation is reflective foil-faced. |

There are many situations where radiative heat transfer is important to avoid--for instance, attics or warehouses where the sun heats the building's skin excessively. In conditions like this, just a thin sheet of reflective material can make as much difference as adding many inches of conventional insulation. These are usually called "radiant barriers".

Radiant barriers must have a low emissivity (0.1 or less) and high reflectance (0.9 or more). Thus they are shiny reflective or white materials.

They only reduce radiative heat transfer. Because of this, reflective insulation is only useful on the surface of insulation facing a cavity or the outside air.

Convection and Insulation

Convection through fluids (like air) can also transfer heat. Unwanted convection through the building envelope can cause unwanted heat gains or losses through infiltration (see Infiltration & Moisture). Also, suppressing convection within the materials of the building envelope is often what makes insulation effective.

Convection within the building envelope hurts insulation as well. Still air is an excellent insulator, so good insulation often uses small pockets of air. The main reason that foam insulation is a better insulator than batt insulation is that there is less convection of the air within foam. Aerogel is such a high-performance insulator because it is mostly air, but the micro-scale structure of the aerogel prevents convection of the air held in it.

Fibrous or cellular products prevent conduction by keeping air still (preventing convection). Here’s how:

- Batt insulation traps air in a mat made from a low conductivity solid, such as glass or organic fiber (wool or polyester).

- Open-cell foams trap tiny bubbles of air or other gas in a poor conductor, such as polystyrene or polyurethane. However, gas can still migrate through open-cell foams.

- Closed-cell foams, where gas cannot travel from cell to cell, are the best way to avoid convection.

Insulation Materials

Although insulation can be made from a variety of materials, it usually comes in five physical forms: batting, blown-in, loose-fill, rigid foam board, and reflective films. Each type is made to fit a particular part of a building.

|

Batting / Blankets |

Form Factor & Installation: In the form of batts or continuous rolls that are hand-cut or trimmed to fit. Stuffed into spaces between studs or joists. Material: Fiberglass is manufactured from sand and recycled glass, and mineral fiber ("rock wool ") is made from basaltic rock and/or recycled material from steel mill wastes. Even recycled cotton fibers from jeans are used. Available with or without vapor and flame retarding facings. |

|

Blown-in/ Loose-Fill |

Form Factor & Installation: Loose fibers or fiber pellets are blown into building cavities using special pneumatic equipment. The best forms include adhesives that are co-sprayed with the fibers to avoid settling. Material: Fiberglass, rock wool, or cellulose. Cellulose is made from recycled plant material (such as newspaper) treated with fire retardant chemicals. Benefits: Can provide additional resistance to air infiltration if the insulation is sufficiently dense. |

|

Foamed in Place |

Form Factor & Installation: Sprayed directly into cavities within the building, where it expands as it sets to fully seal the cavity, filling all nooks and crannies. Material: Polyurethane or polyisocyanurate. Some brands are partially made from bio-plastic rather than fossil-fuel-derived polyurethane. However, the percentage of bio-material is generally no higher than 10 - 15%, as there are currently not yet viable bio-based alternatives to the bulk of the polyurethane polymer. Benefits: It can fully seal the cavity, helping to reduce air leaks. Spray foam, once set, is rigid and can even provide some structural shear strength. It generally has high R-values, and also provides acoustical insulation. |

|

Rigid Board |

Form Factor & Installation: Plastic foams extruded into boards, or fibrous materials pressed into boards. Can also be molded into pipe-coverings or other three-dimensional shapes. Rigid board provides both thermal and acoustical insulation, strength with low weight, and few heat loss paths if it fits the installation location well. Material: Polyisocyanurate, polyurethane, extruded polystyrene ("XPS"), expanded polystyrene ("EPS" or "beadboard"), or other materials. May also be faced with a low-E reflective foil. Benefits: Lightweight, provide structural support, and generally have a high R-values. Can be used in confined spaces such as exterior walls, basements, foundation and stem walls, concrete slabs, and cathedral ceilings. |

|

Reflective |

Form Factor and Installation: Roll of foil, integrated into housewrap, or integrated into rigid insulation board. These "radiant barriers" are typically located between roof rafters, floor joists or wall studs. Material: Fabricated from aluminum foil with a variety of backings such as craft paper, plastic film, polyethylene bubbles or cardboard. Benefits: Resists radiative heat transfer. The resistance to heat flow depends on the heat flow direction--it is most effective in reducing downward heat flow2. Radiant barriers are installed in buildings to reduce both summer heat gain and winter heat loss. They are most effective in hot climates rather than in cool climates. |

Working Together

Different forms of insulation can be used together. For example, you can add bat or roll insulation over loose-fill insulation, or vice versa. Usually higher density insulation should not be placed on top of lower density material that is easily compressed. Doing so will reduce the thickness of the lower insulation and thereby reduce its R-value.

Since hot air rises by convection, hot air generally pools at the undersides of surfaces and conducts heat upwards into those materials. Radiant barriers only resist heat transfer by radiation, they cannot resist conductive and convective heat flow. Thus they are more effective at preventing heat from flowing downward through spaces than upward.

Movable Insulation

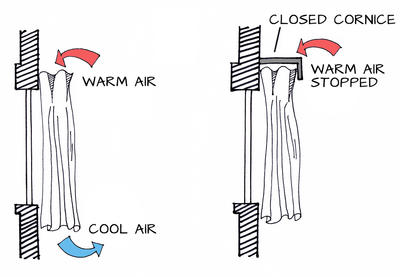

|

| Closed cornice board over curtains |

Windows often provide valuable heat gain during the day but cause problematic heat loss during the night. One way to prevent this is movable insulation, in the form of insulated shutters or movable walls, insulated internal or external roller-shades, or--most commonly--thick curtains.

Curtains often have a fatal flaw of allowing air convection around them. Cold air between the curtain and window sinks, falling under the bottom of the curtain into the room, and warm air from the room is sucked from above the curtain into the space between it and the window, to repeat the cycle. This is solved by having a closed cornice board or "pelmet" sealing the top of the curtains.

Links and References

- A listing of R-values from ASHRAE’s 1997 Handbook of Fundamentals, published by Arch Toolbox.