You are here

Heat pumpsmove heat from one place to another. Some can pump heat both out of and into a building, for cooling or heating. Air conditioners(or "chillers" for large-scale systems) are a kind of heat pump that can only pump heat out of a building, but can do it slightly more efficiently than bi-directional heat pumps.

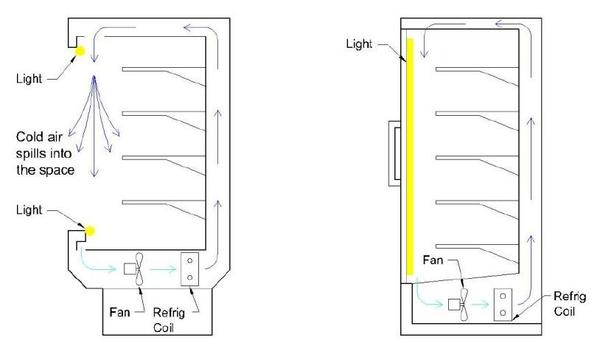

Small-scale heat pumps.

Heat pumps are important for efficient HVAC systems because moving heat can use less energy than generating heat. Heat generators can never be more than 100% efficient because the energy they use is directly creating heat, but heat pumps effectively can because they just move heat from one place to another. However, based on the operating environment, sometimes boilers are more effective. This is the case particularly in cold outdoor temperatures (below 5°C or 40°F).

To think about moving heat rather than generating it, imagine a tanker truck driving fuel from one place to another--the truck may be hauling thousands of liters of fuel as cargo, but truck's own gas tank only holds a few dozen gallons, because that's all the fuel it needs to burn to carry the load to its destination. In the same way, heat pump move heat energy as cargo, using a bit of electric energy to do so.

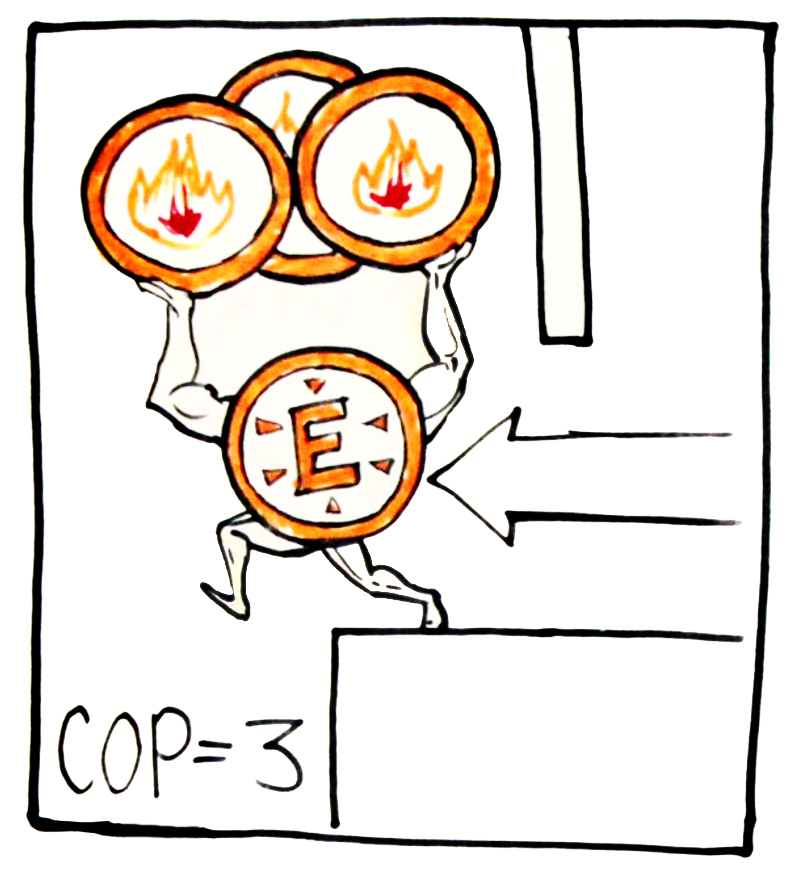

Heat pumps can move several units of heat energy per unit of electricity

Measuring Efficiency

There are many ways to measure the effectiveness of a heat pump:

COP (coefficient of performance) is the simplest measurement. It measures the amount of heat energy moved (in watts), divided by the electric energy used to move it (also in watts), at a given outdoor temperature. Higher COP values indicate a more efficient system. An electric resistance heater generating heat at 100% efficiency will have COP = 1, while a heat pump in heating mode ranges from a COP of 2 to 5, and a heat pump in cooling mode ranges from 3 to 12.

EER (energy efficiency ratio) is similar to COP, but for only for cooling. It measures how efficiently a cooling system operates. EER is most commonly applied to window units and smaller standalone air conditioners and heat pumps. The EER is the ratio of Btu/hr of cooling divided by the watts of electricity used at an outside temperature of 95°F (35°C). Room air conditioners should have an EER of at least 9.0 for mild climates and over 10.0 for hot climates.

SEER (seasonal energy efficiency ratio) measures how efficiently a smaller residential air conditioner or heat pump operates over an entire cooling season, as opposed to a single outdoor temperature. As with EER, a higher SEER reflects a more efficient cooling system. SEER is the ratio of the total amount of cooling Btu's the system provides over the entire season divided by the total number of watt-hours it consumes.

HSPF (heating seasonal performance factor) measures how efficiently heat pumps operate in heating mode over an entire heating season. It is like SEER but for heating. The higher the HSPF, the more efficient the system. HSPF is calculated by dividing the total number of Btu's of heat delivered over the heating season by the total number of watt-hours of electricity required to deliver that heat.

kW/ton measures the energy input in kW over the tons of cooling provided. Unlike other metrics, the lower the ratio, the more efficient the chiller. This metric is most often used to determine efficiency of large-scale chillers.

| Operating Mode | Design Rated Conditions | Seasonal Average Conditions |

| Cooling |

COP

EER

kW/ton

|

COP

SEER

|

| Heating | COP |

COP

HSPF

|

Table of different heat pump efficiency measures(from Engineering Toolbox)

How Heat Pumps Work

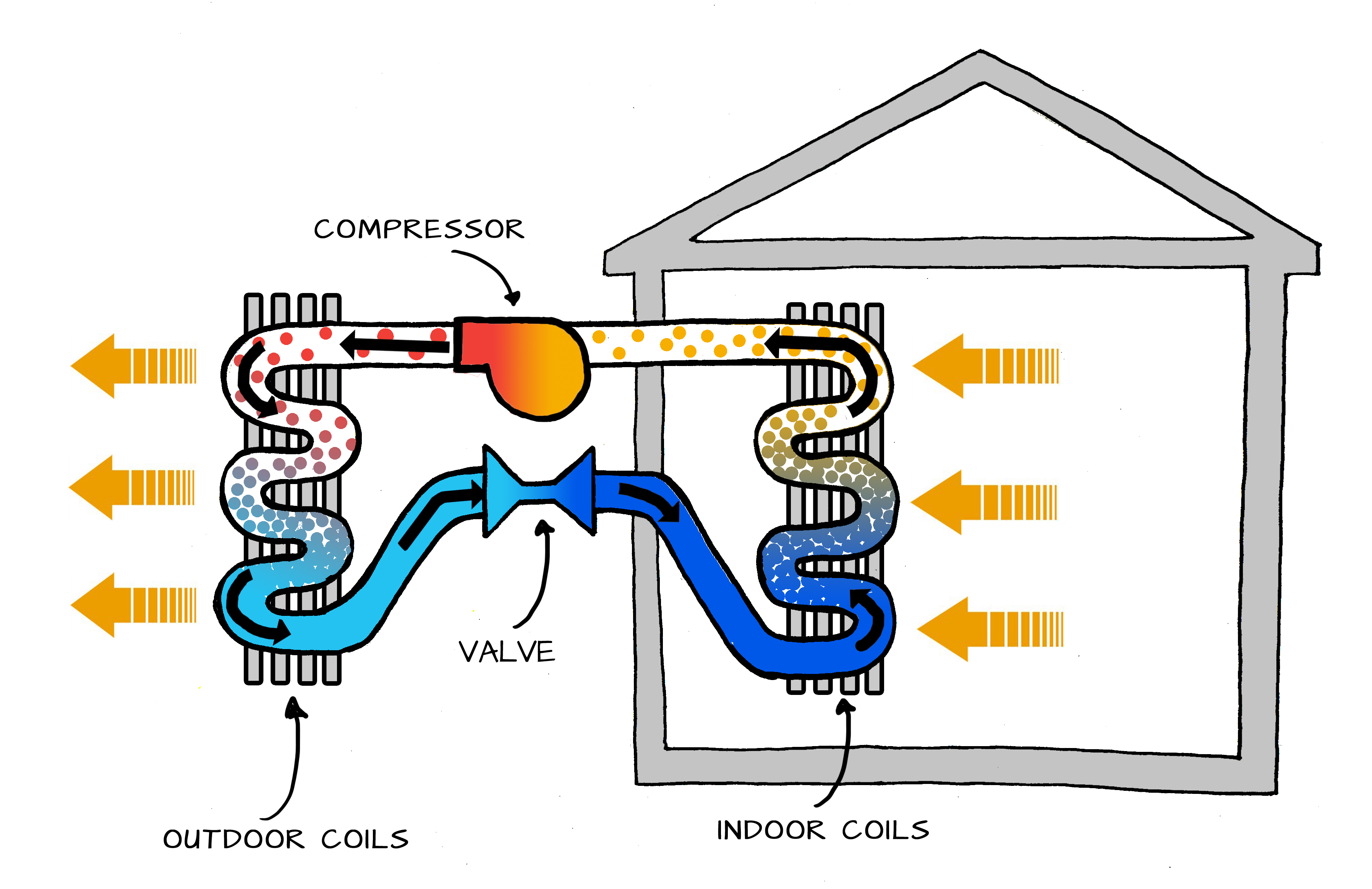

Heat pumps work the same way a refrigerator does--by having a gas condense to liquid and then expand again, within a loop of rigid tubing that extends from the hot side to the cold side. This moves heat because of the ideal gas law, which says that as pressure increases, temperature increases; as pressure decreases, temperature decreases.

Thus, when the gas expands on one side of the tubing loop, its temperature decreases and it pulls heat into it from the surroundings. This becomes the cold side of the loop. The gas is then pumped to the other side of the loop and pressurized by an electric compressor until it becomes a liquid. This rise in pressure raises the temperature, so the liquid pushes heat out to its surroundings. This becomes the hot side of the loop. After dumping its heat outside, the fluid goes through a valve to allow it to expand to a gas again on the other side of the loop, starting the cycle over.

Diagram of a heat pump cycle, in cooling mode

Diagram of a heat pump cycle, in heating mode

In theory, one side of the tubing loop is indoors while the other is outdoors, but in reality this is usually costly and difficult to plumb, because the loop's "working fluid" is a volatile gas. These gases should not be allowed to escape, because they usually have adverse environmental impacts such as climate change and ozone depletion. Thus, usually both sides of the loop are in the heat pump unit, and the "indoor" side contacts indoor air brought to it by a duct, or contacts a separate loop of water that circulates to ducts or radiant systems.

Heat Pump Sources

Air

Air-Source Heat Pumps dump their exhaust heat (or cooling) to the outside air. They are the vast majority of heat pump systems. For large chillers, the unit dumping heat into the outside air is usually called the cooling tower.

Cooling tower for a moderate-sized commercial HVAC system

Air source heat pumps are popular because they are the least expensive and easiest to install, as they do not require digging into the earth or extensive piping systems. However, they lose efficiency when heating buildings on cold days (below 5°C / 40°F).

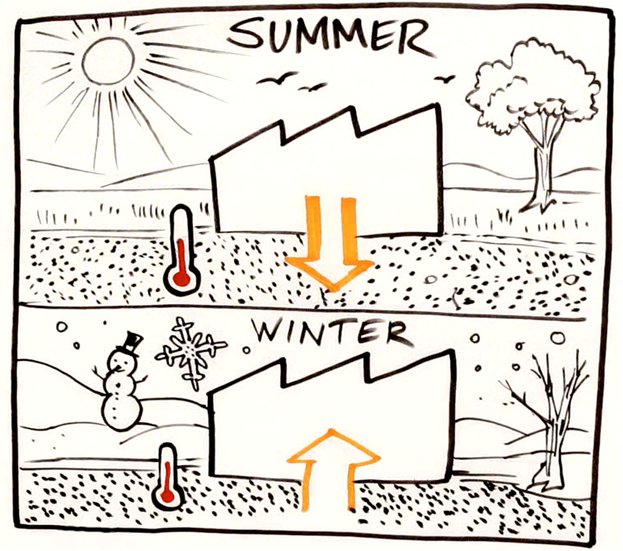

Earth

Ground Source Heat Pumps(“GSHP”, or “geothermal” heat pumps) dump their exhaust heat (or cooling) to the ground instead of the air. Because the ground stays at a relatively stable temperature all year, they can be much more efficient than air source heat pumps on very hot or cold days.

Ground temperature stays relatively constant while air temperature varies wildly

All ground source heat pumps work by pumping a heat-conductive fluid (usually water or propylene glycol) through loops of pipe in the ground. "Horizontal" systems install the pipes by digging a shallow (1-3 m / 3-8 ft. deep) but wide trench in the ground, laying coils of pipe, and covering it back up with earth. "Vertical" systems dig deep but narrow wells (usually 30-150 m / 100-500 ft. deep). Horizontal systems are less expensive to install, but take more land area and do not have as stable ground temperature as deeper wells.

Installing horizontal (top) and vertical (bottom) plumbing of ground source heat pumps (wikimedia commons source)

The disadvantage of ground source heat pumps is that the digging and plumbing required to install them is expensive. A medium-sized commercial building might require hundreds of wells to be dug and plumbed for a GSHP system.

Water

Some ground source heat pumps actually use rivers, ponds, or other bodies of water for their heat sink. Closed-loop systems use effectively the same hardware and work the same way as ground source heat pumps.

However, it is also possible to install “open-loop” systems, whose pipes are literally open to the stream. These pull water in one end, bring it to the heat pump where heat is dumped into it or pulled from it, and pump the newly heated or cooled water back into the river downstream. These can also use groundwater from separate wells, pumping from one into another.

Installing a water-source heat pump by sinking coils of pipe

Water-source heat pumps have the performance advantages of ground-source heat pumps, and can even perform better due to water’s high conductivity and high heat capacity. They can also be less expensive to install, depending on the local conditions. However, they are of course limited to sites where a body of water (or hidden groundwater) is convenient, and where the extra heating or cooling will not disrupt the water’s ecosystem.

Absorption Chillers

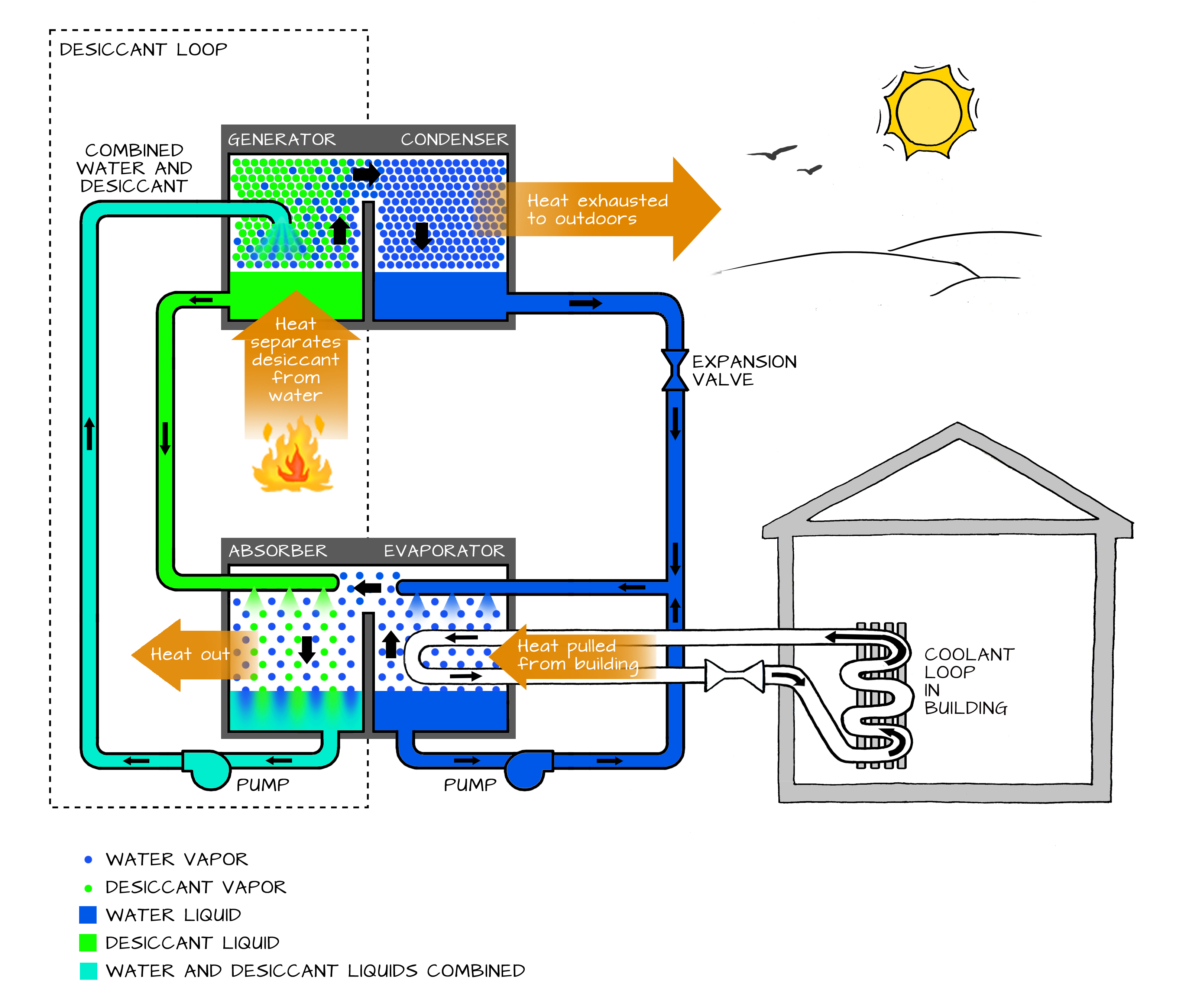

Absorption chillersare heat pumps in which the compression and evaporation of the working fluid is not controlled by an electrically-powered pump, but instead driven by an external heat source.

In absorption chillers, the gaseous working fluid is absorbed by a second chemical, such as ammonia, which brings it back to a liquid state. The second chemical is then driven off by heat and the working fluid is returned to the cooling loop as a liquid.

An absorption chiller's dual cycle. (Click to enlarge.)

Absorption chillers are significantly less efficient than electrically-pumped units (with COPs around .7 to 1.2), but they can operate off of waste heat. In these cases, their efficiency is unimportant, because the energy source is free and does not cause any environmental impacts to use.

This is the same technology used by gas-powered refrigerators.