You are here

Lighting operations and maintenance ("O&M") are the practices that keep lighting systems working at peak performance during the life of the building. As a designer, your choices can make it easy or hard to maintain your lighting system.

Lighting design is only as good as its execution. Good operations and maintenance are necessary to keep the lighting systems working as designed through the years. Neglect, poorly-chosen replacements, and misunderstanding of systems can undo all the improvements of good lighting design.

Good lighting O&M is measured by system performance. The system should continue putting out the lux or foot-candles of illumination in the proper places while using the watts of electricity specified in the lighting design for the building. Commissioning agents usually perform these audits. As technology improves, the performance may even be improved to exceed design specs.

Operations Manuals

Good design process can help ensure good operations and maintenance routines. The lighting designer should create a manual for operations staff that makes the lighting design intent clear, lists maintenance and replacement schedules, and makes it clear what parameters should be measured during commissioning, as well as how often such measurements should be done.

Green buildings often do not perform as well as predicted during the design. Without a manual, operations personnel are left to troubleshoot systems through piecemeal guesswork. This is never as effective as the whole-systems approach that can be laid out by an operations manual.

Schedules

An important part of the O&M manual is schedules for cleaning fixtures, replacing bulbs, and measuring energy use and lighting levels. Performance measurements should be done monthly or at least quarterly, to provide operators with enough data to tell when systems are beginning to perform poorly.

Flexibility

When building occupants bring in their own lights, it may be an indication that the lighting system is not working as designed, or was not designed to meet the current users' needs. Have the flexibility to work with users to meet their needs while ensuring energy efficiency. This may mean changes to the original design, or helping occupants choose efficient products for their personal use.

Cleaning

Keeping lamps and fixtures clean may be the most important factor in keeping their performance high. However, it is often neglected. Walls, ceilings, and other lit surfaces should also be kept clean, as their reflection of light is sometimes as important as the fixtures themselves.

Clean bulbs and fixtures with soft moist cotton cloth, soft-bristled anti-static brush, or low-power vacuum cleaner.

Replacement

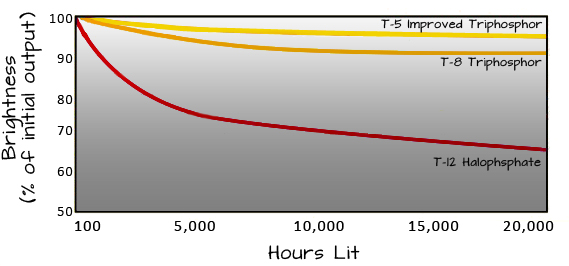

Bulbs should be replaced not only when they break, but on a schedule according to how the brightness of the lamp decays over time. Some bulbs lose over a third of their initial brightness over a few years.

Brightness of various fluorescent bulbs decaying over time

When replacing bulbs, bulk purchases can significantly reduce costs for the same quality products. Scheduled replacement also facilitates this.

Be sure to dispose of replaced bulbs properly, as many fluorescents and other electric discharge lamps contain mercury. Handle the bulbs carefully to avoid breaking them in transit, and take them to approved recycling centers or arrange for pickup.

As technology improves, replacements are an opportunity for upgrade. Be sure to refer to the original lighting O&M manual to follow the design intent for the whole system. Use evidence-based recommendations for upgrades, such as lighting audits. New bulb technologies often require new fixtures. When replacing lighting systems, balance installation costs with lifetime energy savings.

Operation of Control Systems

Lighting control systems are often run by timers. Such timers should be set to match the activity schedules of different spaces. These schedules change over the years as building use changes, and controls schedules should change to match.

Sensors for daylighting controls, such as occupancy or brightness sensors, should be regularly checked for proper operation. Sensors that start shutting off or turning on lights at the wrong times get manually disabled by occupants, and are no longer able to do their jobs.

Diagrams

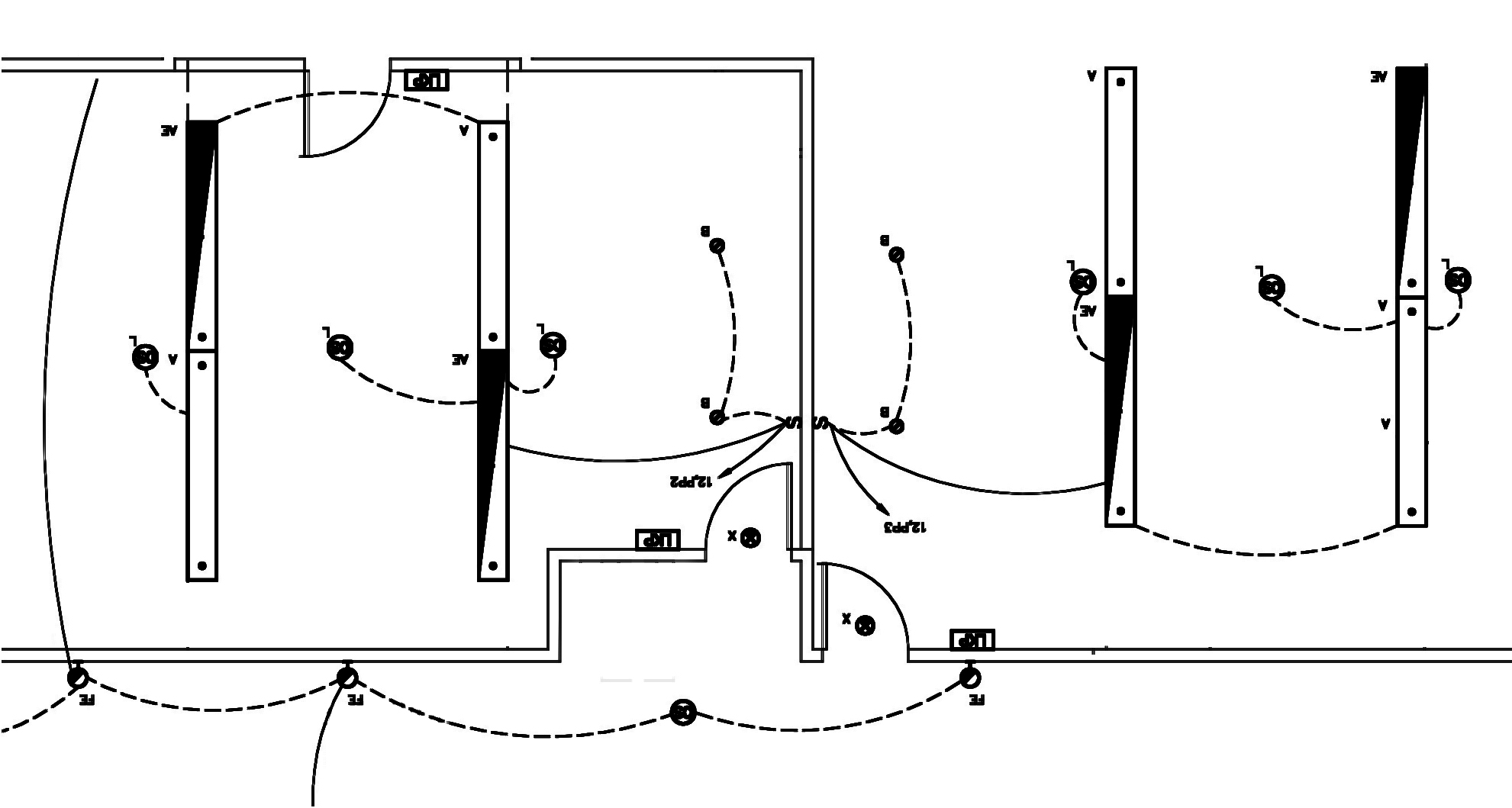

Lighting control and wiring diagrams should be created and kept updated, to ensure control systems are easy to understand. This not only makes it easy to troubleshoot problems, but also helps plan replacement schedules and can aid in system upgrades.

These diagrams should include the fixtures, sensors, controller units, and how all these components connect to each other, as well as boundaries of different control zones.

Lighting plan