You are here

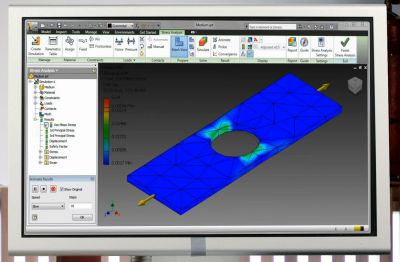

Stress analysis can help predict if, when, and where things will break. You can use it to test if your design will be durable. This is especially important when lightweighting, so you ensure your lighter weight design does not compromise strength.

Finite Element Analysis for Stresses:

Stress analysis in simulation software is based on finite element analysis (FEA). FEA breaks up your geometry into simpler parts that the computer can more easily analyze.

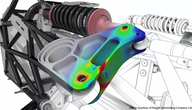

Think of overlaying a grid of triangles on a cell phone housing and then analyzing how those “finite elements” (each triangle, connected at nodes) will react as a load propagates through them. What happens when you sit on it? What happens when you drop it from five feet? What happens if it lands on the corner? FEA results are visualized with a color gradient so you can see areas of maximum and minimum deformation and stress.

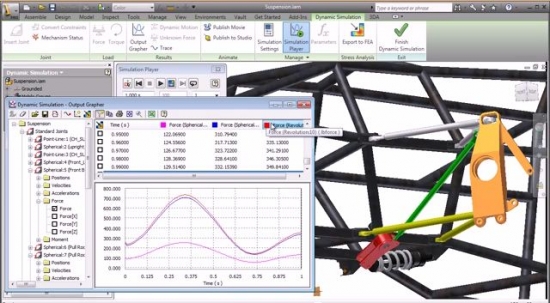

FEA simulations use numerical methods to approximate solutions to the complex partial differential equations that describe the behavior of solids and fluids.