You are here

CFD meshing is the process by which the simulation volume is broken up into discreet chunks. These chunks are then solved together, iteratively, until they reach a steady state solution, known as convergence. The definition of these chunks, or “cells,” is one of the most important aspects of running an accurate and computationally manageable analysis.

Automatic Meshing and Mesh Refinement

As in FEA, the initial step of CFD meshing is often to have the software create an automatic mesh distribution. This mesh is often too course in places, and may also too fine in others. Mesh refinement in CFD is quite similar to FEA, and can be handled in much the same way by using the built-in mesh refinement tools.

A mesh that is too coarse won’t have enough precision to produce correct simulation results. Such a mesh will often create results that are noticeably jagged or show other clear artifacts that indicate that there is something wrong. A mesh that is too fine requires so much computing power that it may be prohibitive to run the analysis, or iterate to find a more optimal design solution.

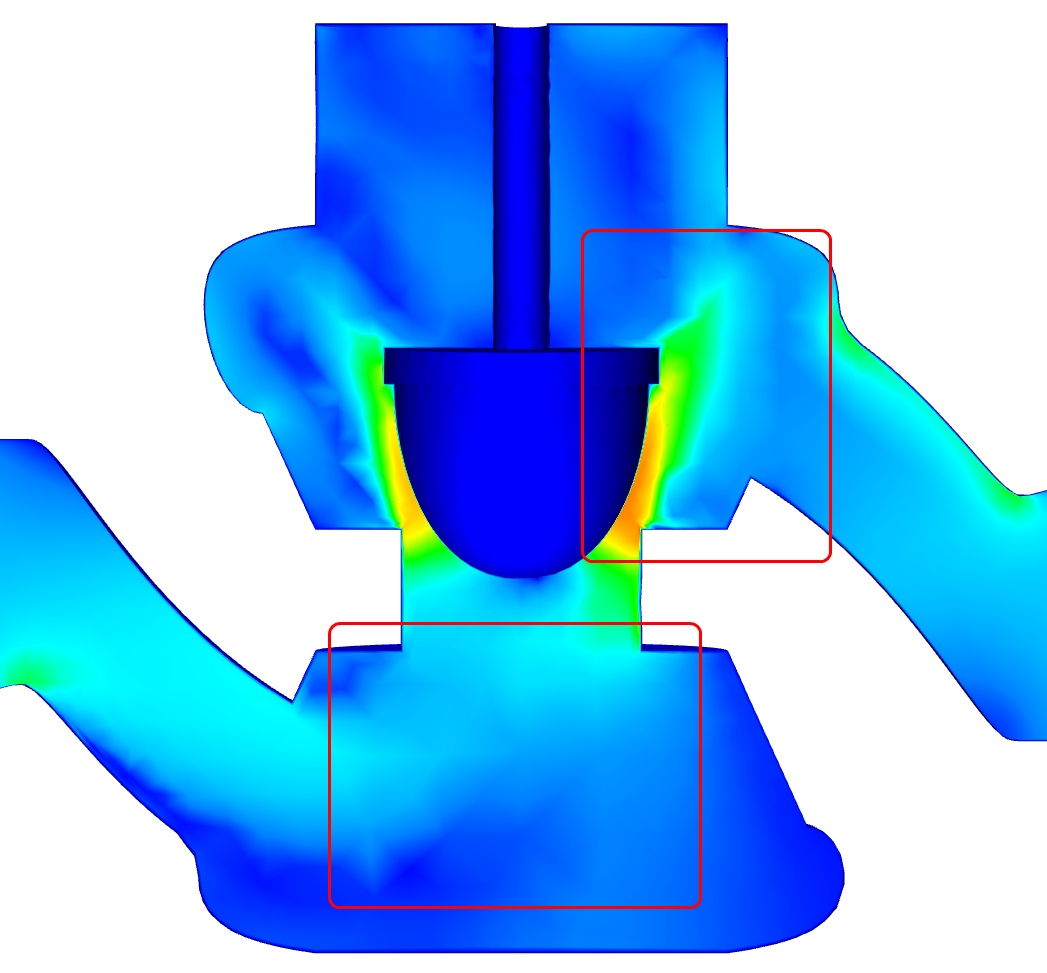

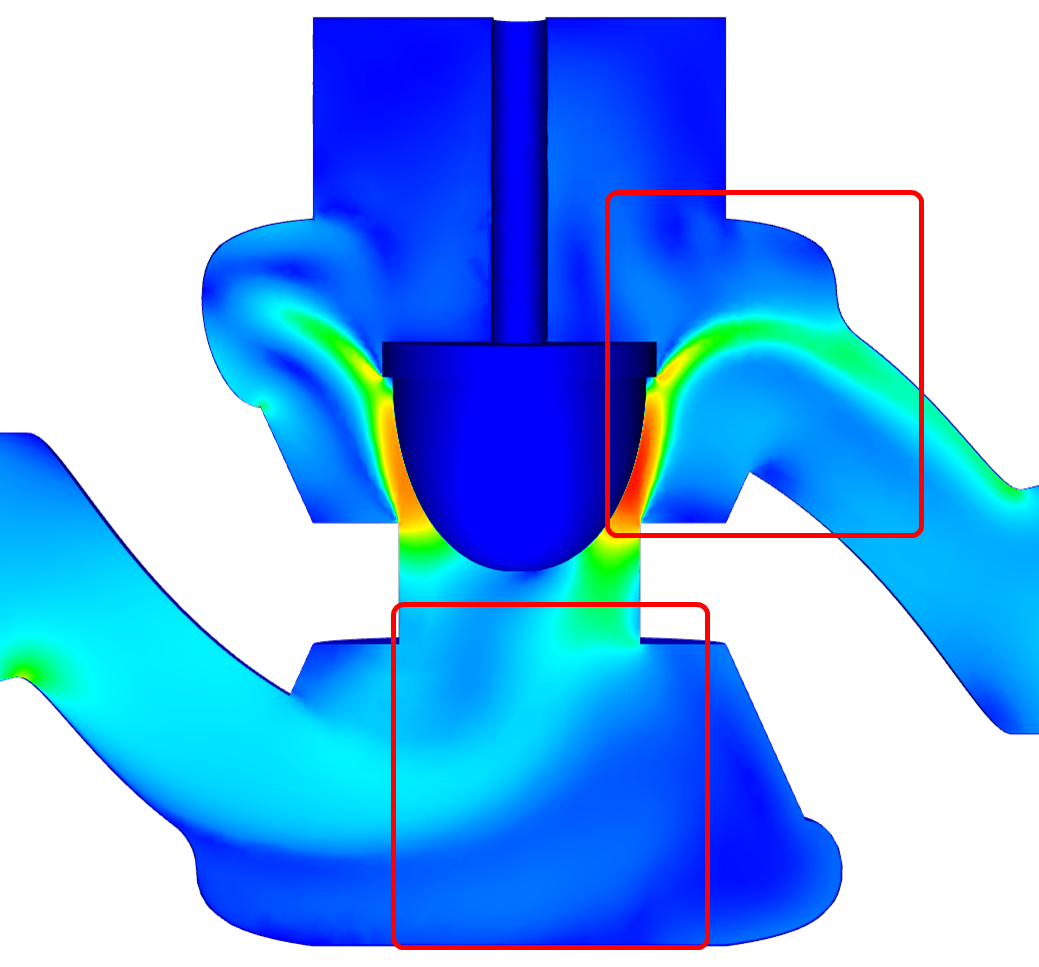

In the first picture we can see the unrealistically jagged and blocky flows that are rectified by using a more refined mesh that gives the results below

Adaptive Meshing

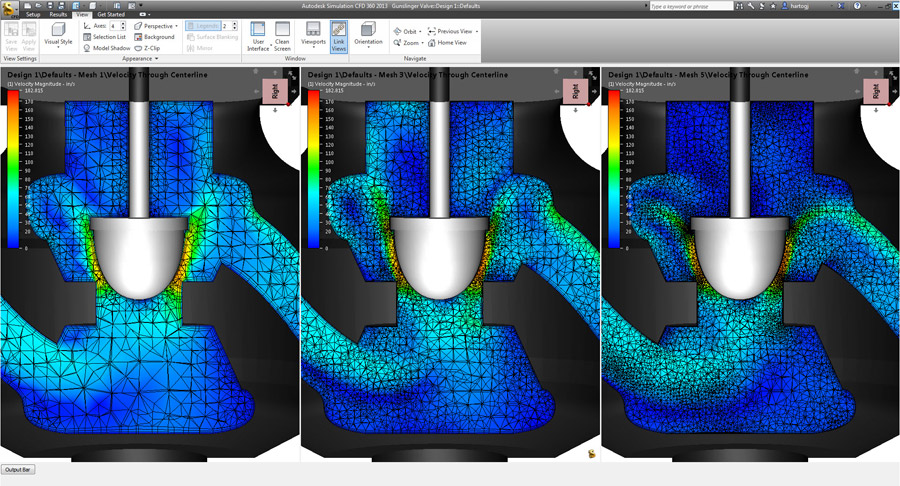

One solution is known as adaptive meshing, which refines the mesh based on iterative simulation results. By running the simulation multiple times, this tool refines only certain areas of the mesh to converge on an accurate solution. Here, we should note the difference between mesh convergence (which means the same as FEA meshing convergence) and solution convergence, which is discussed further in the solving section. For adaptive meshing to be most effective, care should be taken to create a good initial mesh