You are here

Why is Simulation Important for Sustainability?

Sustainability in design and engineering is all about the ability for humans to live within our means. To do so, we must use fewer resources and treat the surrounding environment in a better manner. To accomplish these goals, designers and engineers must use their expertise, along with advanced tools, to reduce the impact of our actions and consumption. One of these tools is computer simulation.

Simulation can play a role in everything from designing more efficient power plants to reducing the amount of material used in a bridge to ensuring that a retaining clip doesn’t fail.

There are many software solutions for these kinds of problems, and knowing the basics of how they work is the key to getting meaningful results.

Finite Element Analysis for Durable Products and Reduced Material Use

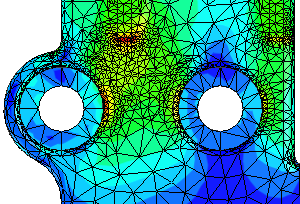

For mechanical design, Finite Element Analysis, or FEA, is often the first simulation tool that is used. Technically, Finite Element Analysis is simply an analytical approach to solving a system of partial differential equations, and solving mechanical problems specifically is known as mechanical stress analysis. However, as in industry the term FEA is commonly used to refer to mechanical stress analysis, we will this term use it throughout these pages.

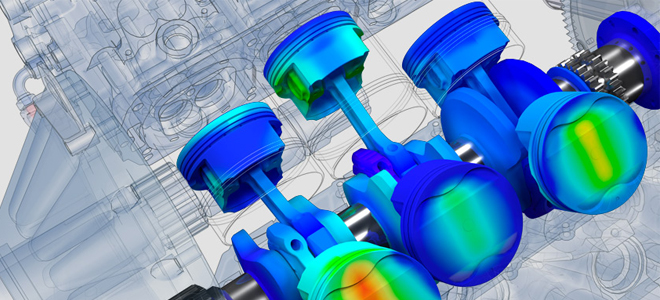

FEA is important in that it allows the designer to determine the mechanical stresses in an object due to a variety of forces. Using this information in conjunction with an understanding of material properties enables engineers to make robust products with the minimum amount of material. This can mean a lower environmental impact from resource extraction, manufacturing, transportation, use, and end-of-life, depending on the product.

Computational Fluid Dynamics for Energy Efficiency

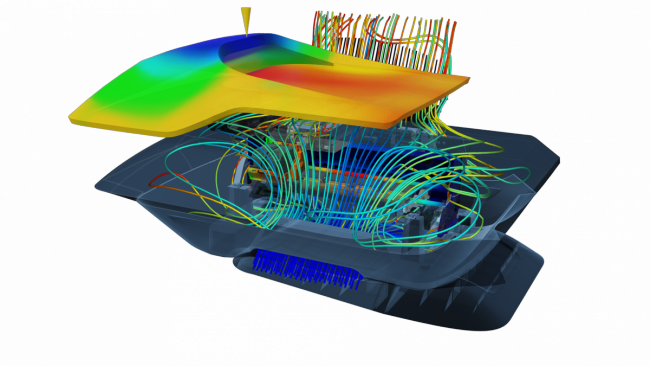

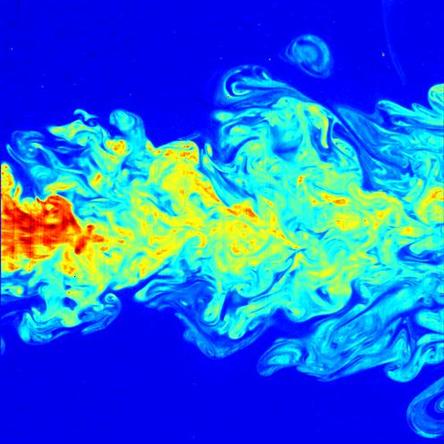

Computational Fluid Dynamics, or CFD, is used to simulate fluid flow. The movement of fluids (examples include air and water), is a very large cause of energy loss in many systems due to drag. Simulation helps reduce these losses. Reducing losses means less energy is needed to power the system as well as lower emissions due to energy creation.

Alternately, CFD can be used to model heat transfer. This is important for optimizing heating and cooling in various situations, as well as optimizing energy generation in applications such as jet engines. Finally, being able to visualize and quantify pressure and flow mixing is essential for a variety of engineering applications, from automotive design to electronics cooling to flow control to AEC ventilation management.

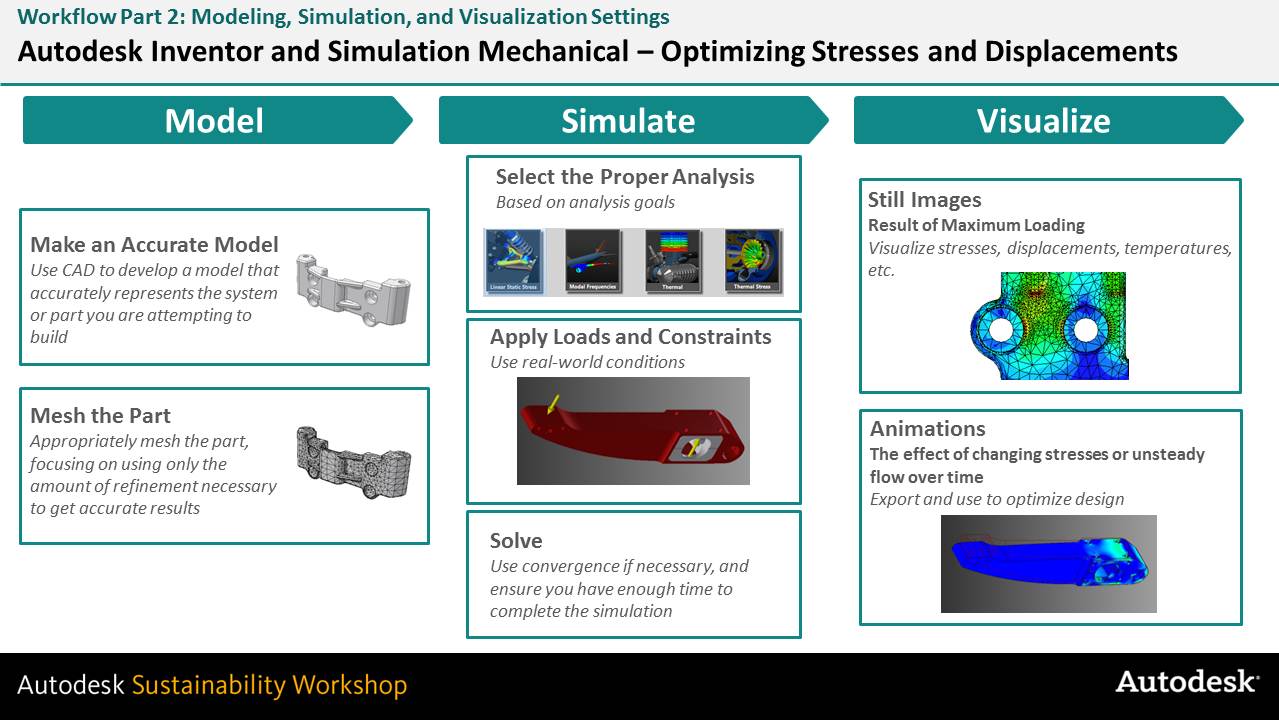

Simulation Workflows

The first thing to determine in selecting your analysis is to know what kind of problem you are trying to solve. Of course, there is more to know than just whether you should use FEA or CFD, such as selecting your analysis type. When you have selected exactly what you need, though, it’s time to move on to actually solving the problem at hand.

In the following sections we will cover the basics of these analytical methods to ensure a good starting point for basic analysis and future in-depth investigation of these topics.