CFD

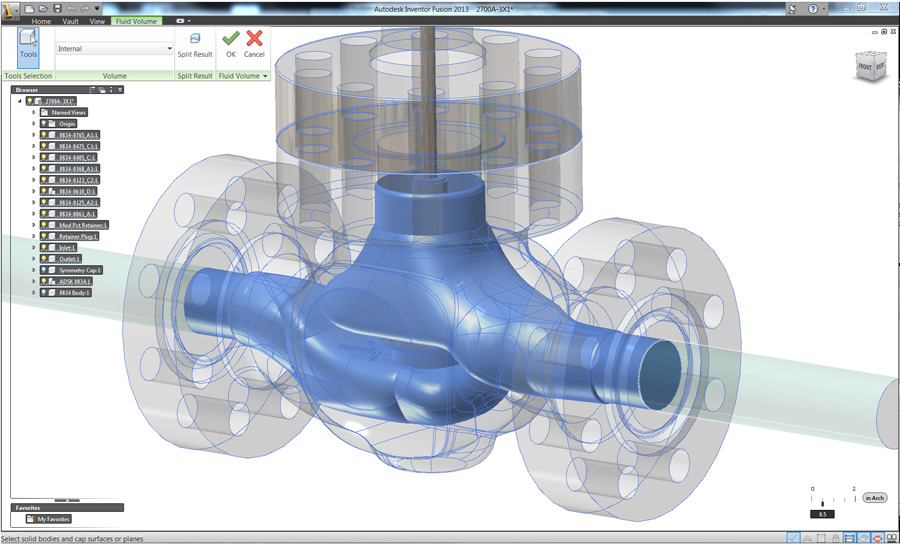

Autodesk® Simulation CFD software (formerly known as CFdesign®) provides fast, accurate, and flexible fluid flow and thermal simulation tools to help predict product performance, optimize designs, and validate product behavior before manufacturing—minimizing reliance on costly physical prototypes and getting innovative products to market faster. Easily explore and compare design alternatives and better understand the implications of design choices using an innovative Design Study Environment and automation tools. Make better design decisions earlier in the product development process with Autodesk Simulation CFD software.

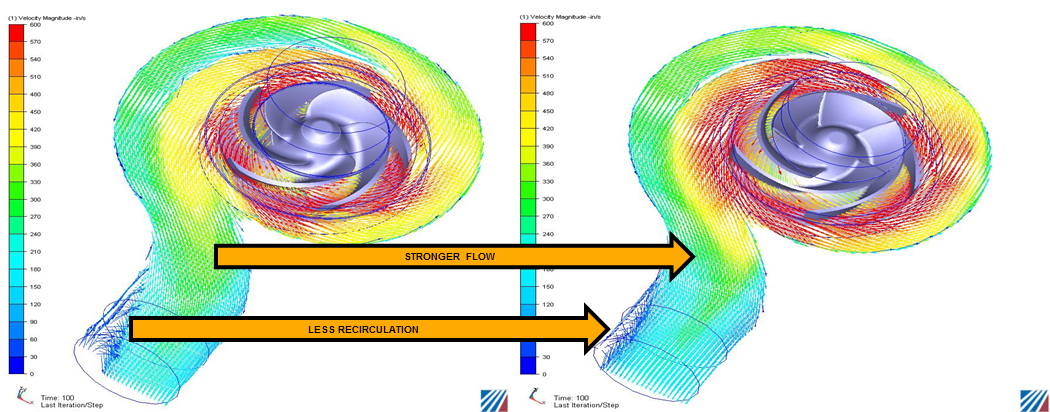

Autodesk Simulation CFD offers a wide range of fluid flow and thermal simulation capabilities to perform fast and accurate simulations of turbulent and incompressible flows, along with conduction and convective heat transfer.

Drive an associative design study within your CAD system or open a single model directly in Autodesk Simulation CFD and leverage a model-centric interface; automated finite element meshing with auto-sizing and auto-refinement; the Accelerant Simulation Engine; and the Design Study Environment for setup, exploration, and decision making. Typical applications include consumer products, automotive, oil and gas, medical, and industrial machinery.

Fluid flow simulation capabilities include:

- Laminar

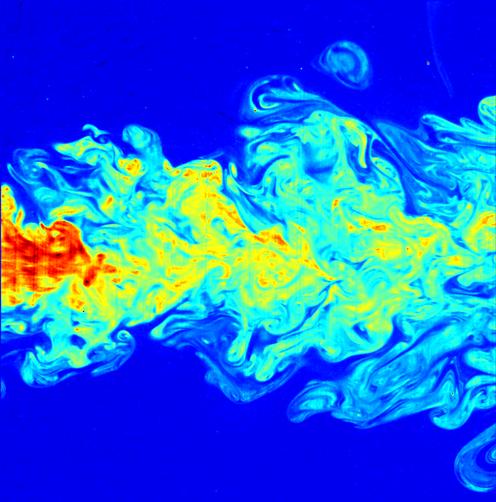

- Turbulent

- Incompressible

- Steady state

Thermal simulation capabilities include:

- Conduction

- Convection

- Forced convection

- Natural convection

You can further expand the fluid flow simulation and thermal simulation tools in Autodesk Simulation CFD with Autodesk® Simulation CFD Advanced and Autodesk® Simulation CFD Motion software.

Software

Autodesk Simulation CFD is a powerful analysis tool that can help improve the energy use and thermal comfort of your design. Learn more about how to use it to optimize airflow and heat transfer in building scale design projects.

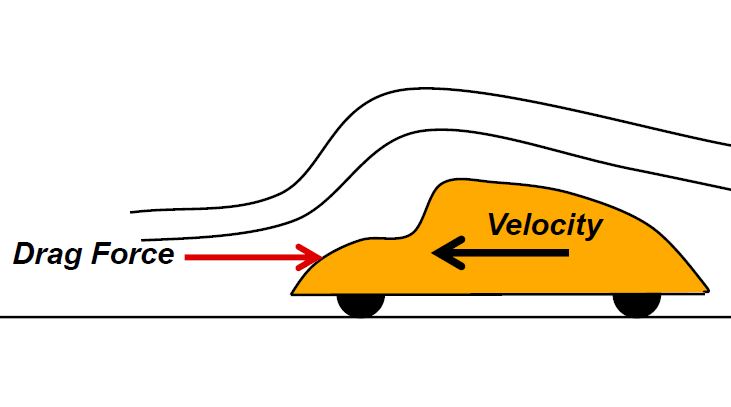

When an object moves through a fluid, there is a force acting on the body by the fluid. The force acts in the opposite direction of the relative velocity between the fluid and the body.

There are many powerful visualization tools in Autodesk Simulation CFD to help you interpret your CFD simulation results, and to make decisions for modifying the design based on the results. These tools allow you to look at different variables in numerous ways to best understand the behavior of the fluid flow.

Using well modeled geometry and having an understanding of the expected simulation results helps the process of achieving a successful analysis. By taking special care with modeling and your simulation setup at the beginning of the analysis process it is possible to save a great deal of time in the long run.

Computational fluid dynamics simulations yield design insights, and allow faster design iteration, without needing as many physical prototypes. Regardless of how you test and optimize your design, understanding the basics of fluid mechanics is essential.

Pages

Project Gallery Examples

This project used analysis throughout the design process to inform design decisions to improve energy use and return a school to the community as a symbol of the Italian village’s identity.

Ventive S is a passive heat-exchanging ventilation system designed for easy home retrofits to increase ventilation while lowering heating requirements.

BioLite is a company using sustainable design practices to build stoves for both avid campers and families in developing countries.