You are here

The benefits of CFD are that it allows you to optimize your designs based on flow dynamics, heat transfer, and pressures without having to build a large number of prototypes. This optimization can improve the energy efficiency and reduce the environmental impacts of the use phase of your product. (Learn about the different impact phases of your designs)

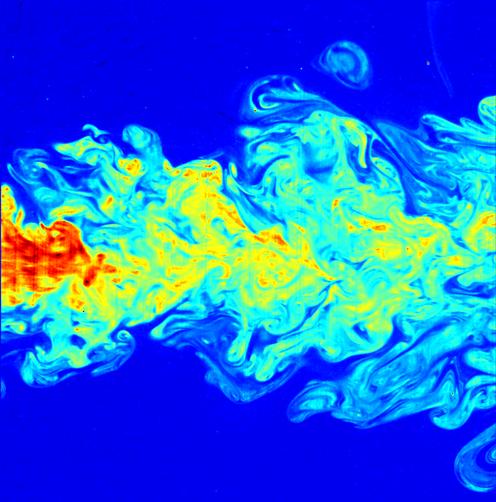

CFD can help improve the energy efficiency, and reduce losses, of objects moving through or around fluids, and vice-versa. For example, when designing a method of transportation, it is important to attempt to reduce drag to minimize energy loss. In other situations, such as in aircraft design, the goal is often to maximize lift, or in racecars, to increase downforce. In both situations, reducing aerodynamic drag is essential to improving fuel efficiency and energy efficiency.

Designing for efficiency by lowering drag is of utmost importance to aerospace companies (wikicommons)

Setting clear goals can help you improve the sustainability of a product using CFD. For example, what is the coefficient of drag you’re striving for based on target fuel consumption?

In certain cases it is important to combine CFD and FEA to ensure a structure is able to withstand loads imparted on it by a fluid. Examples include a flow volume sensor in a water pipe and a building subjected to strong winds. This dual-simulation technique can reduce failure and can also help to avoid “over-building” your designs.