You are here

Interpreting the results is the key to properly utilizing a well done simulation. Assuming all the steps up until this point have been correct this is where the user will get insights to inform the next design iteration.

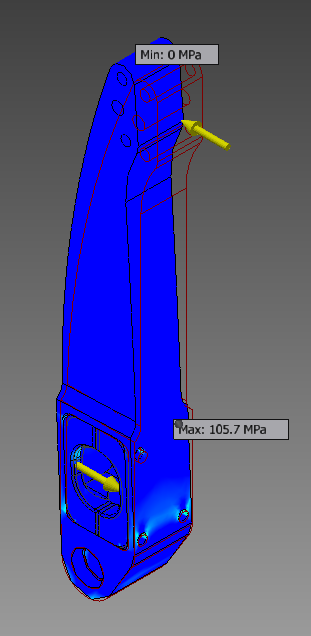

For mechanical applications this may mean determining whether stresses fall within acceptable limits, finding which areas should be reinforced and which can perhaps have material removed. A good rule of thumb for interpreting results is to find the location of the extreme result values in your simulation. You can do this by probing for these values with the software.

Probing for maximum and minimum stresses

From here, use your engineering judgment to decide if those stress values can and should be reduced (to prevent failure), or if there is leeway to increase them (by removing material and reducing weight). This will require a good amount of engineering knowhow and experience, as well as a good understanding of the tool.

Some of the tools available for interpreting results are further explained in this article by Autodesk’s Bob Williams. Autodesk Simulation 360 allows you to capture animations of your simulation for a visual display of your results. Learn how to create these visuals from the following WikiHelp section, which can be especially helpful when analyzing non-linear or dynamic systems.