You are here

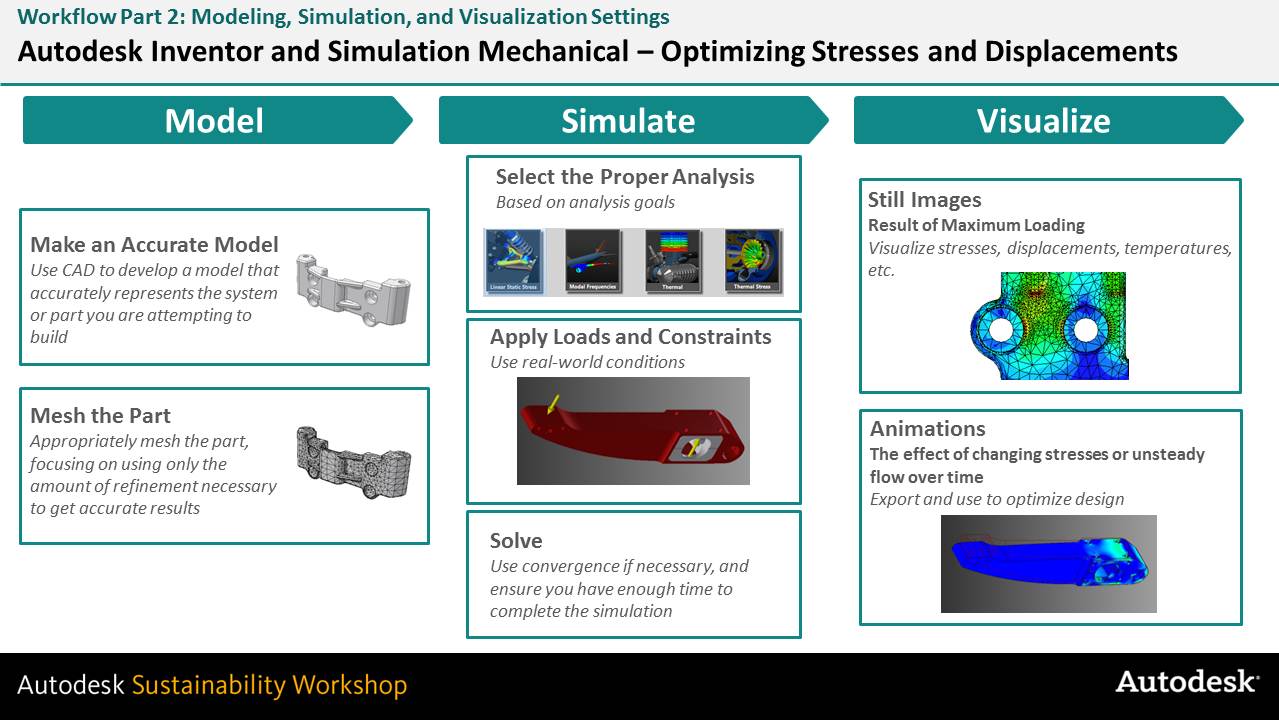

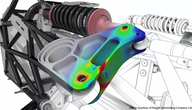

Finite Element Analysis (FEA) is the current industry standard method for solving complex mechanical problems using computers.

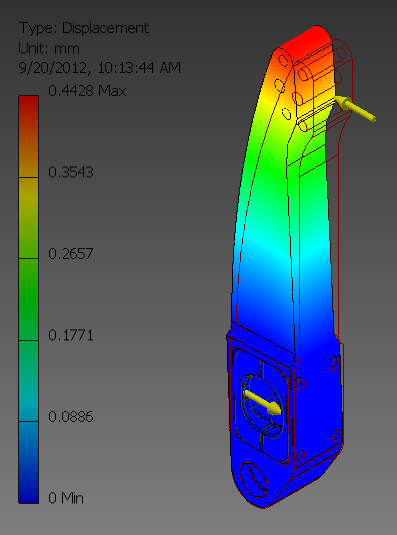

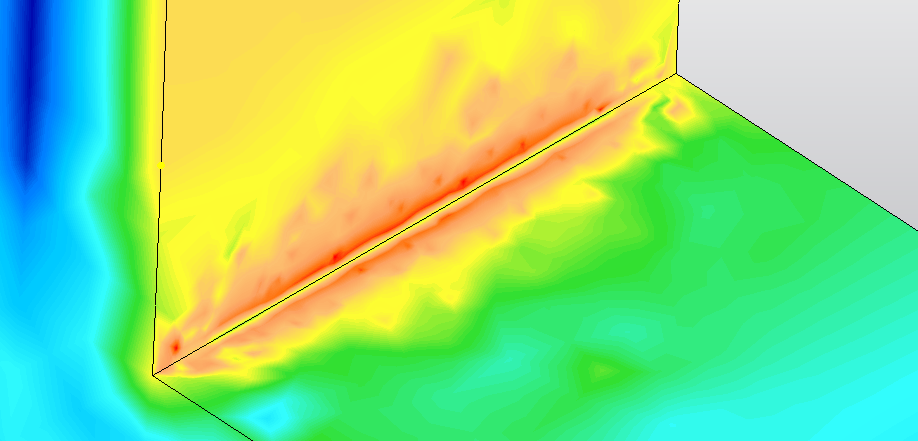

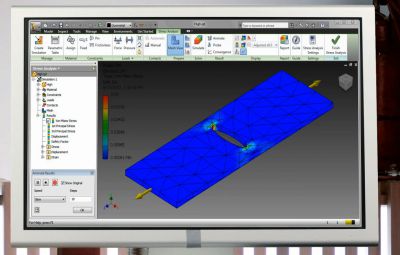

Simply, it works by breaking down a complex problem into a series of much smaller and more easily solvable connected problems. The way that this is done is quite complex, but the computer is able to solve these problems far more quickly than a person attempting the problem by hand, or by building many prototypes to test their design iterations.

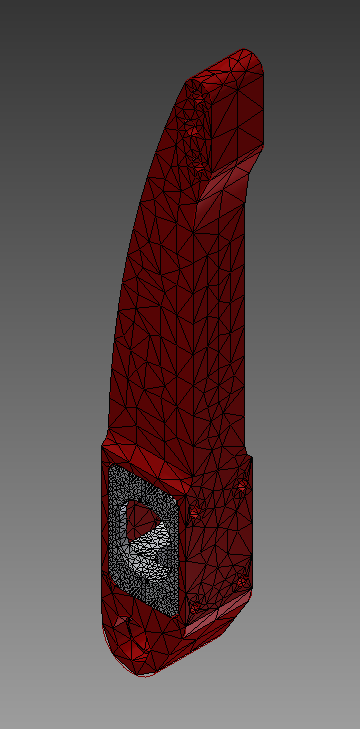

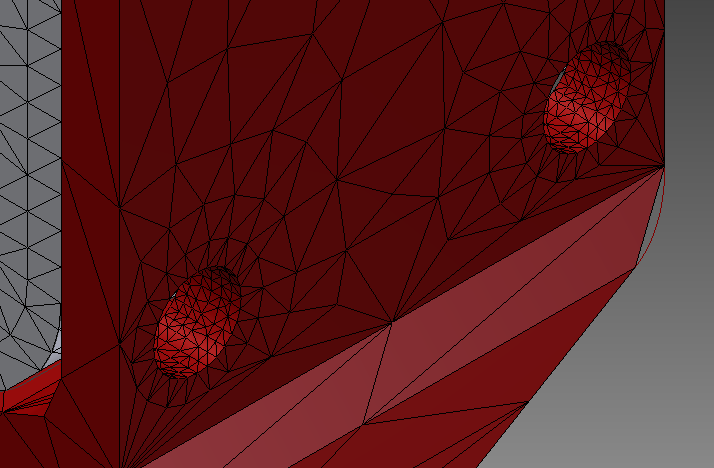

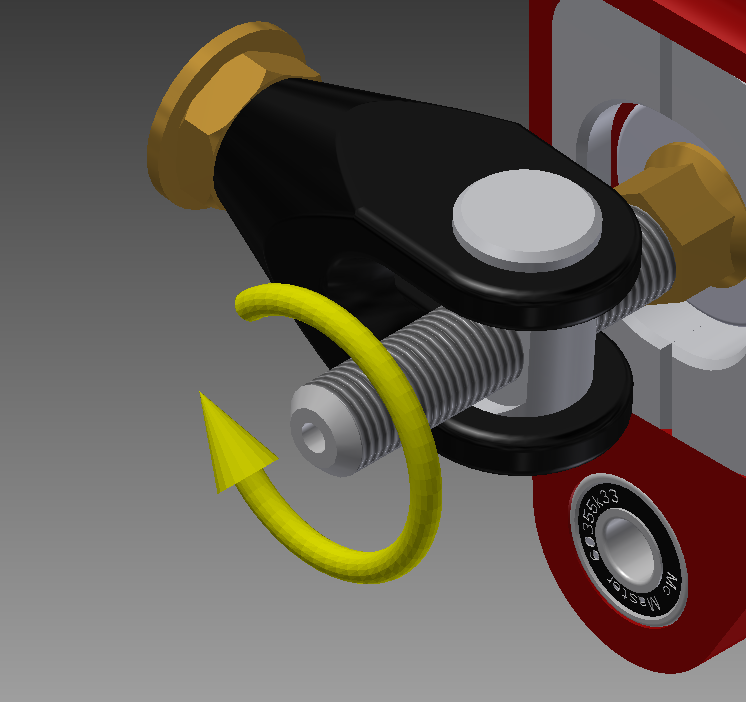

The computer breaks down the problem into a "mesh" and then solves each of the pieces together

FEA is a powerful tool – it is used in practically all engineering applications today – but it must be treated with care and understanding because it is also very easy to get incorrect answers. A saying that is quite common in the industry is “garbage in, garbage out.”

FEA will not tell you if you have set up your analysis incorrectly. This means that, even if you understand all of the math and physics at work, simple mistakes in the initial conditions can yield good looking results that are completely wrong.

For this reason expert users of FEA will always have a good estimate of the results before they begin. This “sanity check” allows them to ensure that the FEA results are on target.

You want to make sure you get something as important as the new Bay Bridge right (credit: baybridgeinfo.org)

In some design applications, getting the analysis wrong can literally cost people their lives. The lessons that you will find on this website are good for a beginning understanding of FEA, but for any part that can affect human safety you MUST consult an expert.

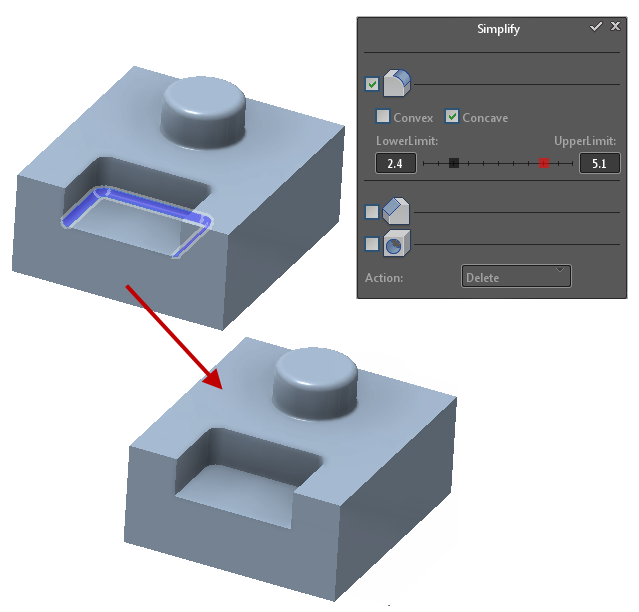

Additionally, parts made using FEA will still need the credibility check of a physical prototype before going into production. There are a number of other problems that can occur during the FEA process. These common errors can result from both user mistakes and limitations of the mathematics and software involved in solving the problem. These problems can occur at all stages of the FEA workflow, and each has a unique way to fix the issue. Through experience, and by using FEA best practices, users can avoid these pitfalls and use FEA more effectively.

However, with a good understanding of FEA, one can design products to use significantly less material in their production, last longer without failing, and use less energy during their lifetime.