You are here

(Download a PDF here)

In 1997, when carpetmaker Interface, Inc. decided to build a new carpet factory in Shanghai, its Dutch subsidiary’s chief engineer Jan Schilham hoped to design the most energy-efficient facility possible. With the help of efficiency experts Eng Lock Lee and Rocky Mountain Institute (RMI), he discovered that by using fat, short, straight pipes to reduce friction, he could cut the pumping energy in the new plant’s main heat-transfer pumping loop by at least 86%. He also found that the cost of this efficiency would pay back in seven days—or instantly if he took credit for making the pumps and motors smaller.

Designers often assume that radical efficiency is too expensive. Yet RMI’s Factor Ten Engineering initiative demonstrates that very large energy and resource savings can be very profitable across a wide range of applications. Factor Ten Engineering uses such innovations to transform design and engineering practice, via whole-system thinking and integrative design.

Whole-System Thinking and Integrative Design

Designers tend to disassemble design problems into their individual pieces. This reductionism, common in Western science, can be useful for developing topical expertise, but optimizing individual parts with little thought to their interactions yields inferior results. As Amory Lovins wrote in Natural Capitalism (1999), “Designing a window without the building, a light without the room, or a motor without the machine it drives works as badly as designing a pelican without the fish. Optimizing components in isolation tends to pessimize the whole system—and hence the bottom line. You can actually make a system less efficient while making each of its parts more efficient, simply by not properly linking up those components. If they’re not designed to work with one another, they’ll tend to work against one another.”

In contrast, whole-system thinking reveals and exploits connections between parts. Whole-system designers optimize the performance of buildings, vehicles, machines, and processes by collaborating in diverse teams to understand how the parts work together as a system, then turning those links into synergies. These engineered systems similarly interact with larger systems (e.g., communities, economies, industries, and ecosystems), which also interact with each other. The more complete the design integration—spanning space, time, and disciplines—the better the result.

Whole-system thinking underpins integrative design that can yield radical resource efficiency. Integrative design optimizes an entire system as a whole, rather than its parts in isolation. This can solve many problems at once, create multiple benefits from single expenditures, and yield more diverse and widely distributed benefits that help attract broader support for implementation.

Examples of Integrative Design

A lighter-weight vehicle can accelerate as fast with a smaller engine while saving fuel, emissions, and (with proper design) lives. The smaller engine’s lower cost can offset the cost of the lighter materials. Superinsulating a house provides better comfort and health with less energy. Shrinking or eliminating the heating system can pay for the superinsulation and superwindows—as demonstrated in more than 20,000 European “passive houses,” some of which even cost less than usual to build.

Applying the 10xE Design Principles

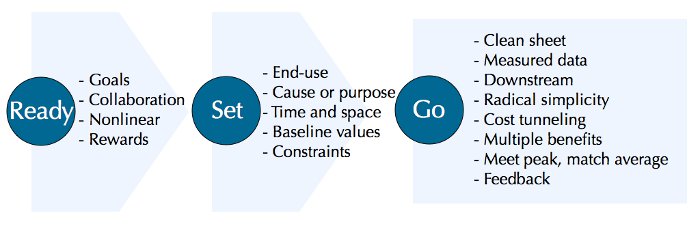

For three decades, RMI and its partners have used whole-system thinking and integrative design to create profitable factor ten solutions. Now, in collaboration with academic and industrial partners, RMI has identified 17 principles for applying this innovative approach to practical design, in three steps akin to the ready-set-go of starting a race:

READY: Create an Integrative Design Process

Before beginning design…

Principle 1. Define shared and aggressive goals

Establish clear, shared, ambitious goals, understood by all, to give the team a unified vision and aspiration. Be transformational, not incremental, and make no little plans: to strive your utmost, choose an aggressive stretch goal. Inventor Edwin Land said, “Don’t undertake a project unless it is manifestly important and nearly impossible.”

For example, eliminating a new building’s mechanical systems and making it a net exporter of clean energy, yet with lower total capital cost, is a worthy goal that can spark designers’ passion; merely cutting another 20% off the previous design’s energy use at higher capital cost probably can’t.

Principle 2. Collaborate across disciplines

For three reasons, real-time collaboration among disciplines and organizations is essential to wholesystem thinking: First, collaboration cross-pollinates ideas and fosters creativity. Second, done effectively, it aligns the design team behind the resulting design solutions. And third, few individuals or single-discipline teams can fully grasp the rich complexity of a whole system. Therefore, convene a unified, transdisciplinary design team with diverse skills and experiences, and make its conversation intensive, iterative, and rewarding for all participants.

For example, convening very early in the building-design process a team including engineers, architect, constructor, landscape architect, interior designer, owner, future building manager, operating staff, and occupants can elicit a wide range of design ideas and perspectives. Then each option can be considered in relation to others and their interactive wholesystem benefits, rather than precluded by narrow choices uninformed by this vital context. Such thinking recently led to eliminating an entire costly floor in a big microchip fabrication plant: the integrative design process revealed that reduced loads and better equipment made so much equipment so much smaller that it could all fit gracefully on one utility floor rather than two. The fab’s 20% energy and 35% water savings came with 30% lower total capital cost—a $230-million saving that let it be built in Texas, not China.

Principle 3. Design nonlinearly

Rather than a simple linear path through a prebaked design process, integrative design is iterative and recursive. Each stage reveals new lessons that illuminate and inform earlier ideas, so the team’s focus loops back, weaving an ever richer tapestry from old and new threads.

For example, the designers of an iron mine found ways to make it all-electric and very efficient. They then realized it could be partly powered by draining its perched water table (a nuisance at the mine but needed at the seaport below) down through turbines. This reduced the remaining energy need enough that it could be met by transporting the ore downhill through a ski-lift-like cable system that recovers nearly all its gravitational energy. Result: a mine that needs no fossil fuels or grid electricity. Yet this was far from an obvious possibility at the start; it emerged only as the pieces of the puzzle were repeatedly reshuffled.

Principle 4. Reward desired outcomes

Clients who want efficiency must vigorously demand and fairly reward it. Treating it as a commodity—or worse, an unimportant afterthought—makes it so. Smart owners invest strongly in efficient design to leverage enormously greater savings in capital and operating costs: front-end thinking is far cheaper and faster than redesigning or rebuilding later. Rewarding designers just for producing documents on-schedule and on-budget elicits relabeled old designs or minor variants. But rewarding designers for what they save, not what they spend, can powerfully motivate creativity, teamwork, and radical imagination. Smart reward structures encourage both risk-taking in designers’ heads and practical, reliable results achieved with intelligent risk management and elegant frugality. New “Integrated Project Delivery” techniques can even align the incentives and relationships of the owner, designers, and builders to create dramatically lower costs, construction times, and risks.

For example, the designers of a state building in Texas were paid not in the traditional way—a percentage of the cost of what they designed or specified—but instead with a share of the measured savings they achieved against preset energy targets, subject to pre-agreed metrics of comfort, health, quality, etc. As a result, they not only produced a great design, but also were motivated by profit to defend their integrative design from “value engineers” (required participants in the process) who tried to pick it apart piece-by-piece. The team showed that cheaper windows would increase mechanical costs even more. Their integrative design was preserved and executed.

SET: Focus on the Right Design Problem

To achieve transformational design, use the following principles to identify what question is to be answered, what is possible, and what is practicable; then refine project goals and repeat.

Principle 5. Define the end-use

Designers often focus on the object to be designed, produced, and sold, not on why its users want it. But behind every artifact is a purpose—indeed, a stack of layered purposes. When you go to the hardware store to buy a drill, probably what you really want is a hole. But why do you want the hole? If you’re trying to hang a picture on the wall, there are many ways to do that; indeed, there are many ways to achieve the purpose for which you wanted the picture hung. Understanding what you’re really trying to do, and why, will help reveal how to do the right steps in the right order.

For example, you’ve been asked to specify an air-conditioner to cool a building. But first, does the building feel hot? No. Only people, not buildings, have a comfort sensation. Nor is cold air the only way to help people feel cooler: air movement, drier air, lower radiant temperature, lighter clothing, less activity, or even a picture of an icy blue waterfall will do that too. Second, what’s making the space hot? Sun-rejecting building surfaces, shading, radiant barriers, insulation, draftproofing, superwindows that sort light from heat, efficient lights and equipment, etc. can exclude or prevent most of the heating. Several passive cooling methods will then suffice in most of the United States. Active evaporative cooling, plus desiccant or absorption dehumidification if needed, will do the job anywhere on Earth. Next cheapest would typically be refrigerative (vapor-compression) air conditioning, plus coolth storage and controls. Yet those standard (and costly) choices are rarely if ever necessary in an integratively designed building that can cut unwanted heat gains by severalfold, then boost cooling efficiency by one or two orders of magnitude—all at generally lower total capital cost and with equal or better comfort. Thus the default solution is seldom the best buy nor even needed.

Principle 6: Seek systemic causes and ultimate purposes

To expand the design space, focus not on proximate means but on ultimate ends. Keep pushing past the layers of end-uses (like heating, lighting, drivepower, transportation), the resulting services (like comfort, visibility, torque, mobility or access), and the ultimate benefits (typically human happiness and satisfaction) until you understand the full range of ways to fulfill the purpose. When diagnosing the challenges involved in a system, use a similar mentality to get past simplistic questions with cut-and-dried design answers. In other words, keep asking “Why?” insistently, until you get to the root of the matter.

For example, a factory’s production halted because a machine failed. The machine failed because a bearing failed. The bearing failed because it lacked lubricating oil. A filter clogged with metal scraps, left by a deficiently trained and supervised maintenance worker, had blocked the oil’s flow. The proximate cause was the bearing failure, but just installing a new bearing only invites future failures unless the deeper flaws in procedures, management, leadership, and perhaps strategy are discovered and fixed too. Solving the wrong problem ensures a suboptimal if not a downright ineffectual result.

Principle 7. Optimize over time and space

Design choices have plumes of consequences, intended and unintended, obvious and surprising, across time and space. Most design processes are challenged to deal with the needs of the obvious stakeholders in the here and now. But for many situations, the more diverse are the actual and hidden “clients” (now and in the future) of whom you’re mindful, and the more you strive to achieve many winners and no losers, the more profound and harmonious your design will be—and the better it will serve different interests, helping attract support and avoid risk.

For example, the German auto industry is now subject to very stringent content restrictions, to ensure that at the end of its life the vehicle can be recycled effectively instead of decorating vacant land. Far from handicapping the industry, rising to meet this challenge has driven a wave of materials innovation and helped solidify the German position as a premier carmaking nation.

In another example, a large hard-cider company sought better ways, not just to make cider, but also to make money. Orchard trimmings being discarded at a cost could instead grow mushrooms more profitable than the cider. Anti-oxidant coatings on the apple seeds, also being discarded, might even be worth more than all the rest of the apple. And long-term economic-development public benefits for the region could outweigh—and reinforce—the private benefits to the cider company

Principle 8. Establish baseline parametric values

Before starting design, calculate and prominently post the whole-system, lifecycle, end-to-end value of saving each relevant resource—a watt of electric power, a kilogram of mass, a liter of volume, a unit of airflow or vacuum or water or exhaust. Once you realize that the whole-system present value of, say, taking a watt out of a cleanroom is (say) $10–20, you’ll design its contents very differently. Reassess these benchmark values, though, as you make the cleanroom far more efficient!

A common pitfall is setting metrics but choosing the wrong ones. For example, the cider plant just mentioned was buying apples by the ton. Ton of what? Not ton of what the process needed (sugar, tannin, and flavorings), but often ton of what only added cost (water content, mud, bruised and fermenting apples, etc.). This unperceived wrong metric had comprehensively harmed both process and profits end-to-end.

Principle 9. Establish the minimum energy or resource theoretically required, then identify and minimize constraints to achieving that minimum in practice

Use physics, chemistry, or building science to determine the theoretical minimum amount of energy or resources needed to provide the chosen end-use or service. Then carefully consider how far each practical design constraint (e.g., cost, safety, performance, accessibility) moves you away from that theoretical minimum. Reduce the list of allowable constraints to the absolute minimum (e.g., safety, operability, and cost) and state them in the most generalized way possible to allow further explorations. Then systematically minimize or evade each constraint. That is, rather than taking accepted constraints for granted and later nibbling around their edges, carefully think through how to vault each constraint in order to yield far greater savings. To eliminate particular constraints, reframe or redefine how to achieve the ultimate purpose of each.

For example, when designing photovoltaic mounting systems to withstand wind loads, rather than just trying to make the structures stiffer and stronger, ask if you can make them windshielded or -shedding or -spoiling, or compliant like a tree, or based on a novel structural concept (such as tension rather than stiffness).

In another example, the theoretical minimum energy required to transport oil through a refinery’s primary distillation unit is roughly ten percent of what is normally used. Some of the 90 percent gap is probably unavoidable due to such constraints as adjacency/separation requirements for safety. However, other putative constraints are avoidable, such as pipe elbows that create friction: these can often be designed out by moving equipment and routing direct diagonal pipes, achieving major practical savings.

GO: Design Integratively

Turn your design intent into action, then keep improving.

Principle 10. Start with a clean sheet

Designers often reproduce inefficient buildings, factories, and systems by starting with a previous or familiar design. To avoid catching “infectious repetitis,” cultivate “beginner’s mind” even when time, cost or other pressures abound. Set aside all conventional methods and assumptions, and jump to a completely new design space with no preconceptions.

For example, when a Soviet missile shot down Francis Gary Powers’s U-2 spy plane in 1960, Kelly Johnson (the aeronautical genius leading the Lockheed-Martin Skunk Works® that had designed the U-2) didn’t say, “I’ll design a slightly better U-2.” Instead, he said he wanted America to own the skies for decades, so he’d design a Blackbird (SR-71); he had no idea how, but would figure out. (It took about 13 months.) He made this bold leap because he knew that design is like a rubber band: if you stretch it too far from where you’re starting, you experience more and more resistance, and ultimately it’ll break. Thus, if you want to get to a new design space, you must jump straight to it, then stretch the rubber band back toward where you are now to accommodate technologies not yet ready for prime time: then as they mature, they’ll relax back toward your goal.

Even the smallest assumptions need reexamination. For example, after winning the first trans-Australia solar car race, the late Paul MacCready griped that he’d messed up the design by having too few flat tires. He’d assumed flat tires were bad. But since his car’s tires could be changed with a bike-like quick-release lever, he should have used thinner treads whose lower rolling resistance would have made the car faster, gaining far more time than a few extra flat tires would lose.

Principle 11. Use measured data and explicit analysis, not assumptions and rules

Develop specifications from data carefully measured for the specific design problem. In God we trust; all others bring data. Data trump assumptions. Check how well previous designs’ actual performance matched initial assumptions, and understand any differences. Question all rules of thumb—often opaque stews of old assumptions, such as cheap energy and obsolete technologies.

For example, widely used HVAC design handbooks’ rules of thumb can oversize air-conditioning by up to an order of magnitude by assuming conditions far worse than modern norms, let alone best practice. As Eng Lock Lee notes, if we designed jumbo jets the way we design chip fabs, with many layers of big safety margins based on loose assumptions rather than prudent margins based on careful measurements, we’d have so many extra engines and sets of landing gear that the plane would never fly. Such excess can defeat the goal: one design of the DDX Naval vessel, for example, was found to go faster without its fourth gas-turbine engine, whose compounded weight and bulk would more than offset its extra propulsive power.

Principle 12. Start downstream

As energy and resources flow from supply to enduse, losses compound through successive steps. Starting savings downstream, at the end-use, turns those compounding losses around backwards into compounding savings—not just of energy but also of capital, because the upstream devices will become progressively smaller, simpler, and cheaper.

For example, a typical data center loses about half its input electricity in uninterruptible power supplies and cooling equipment, half the remainder in inefficient server power supplies and fans, much of the delivered chip energy to underutilization, and much of the computation to bloatware. Starting downstream—with terse code, then efficient servers and their power supplies—eliminates most of the cooling and UPS loads (which also incur half the total capital cost). Leveraging these and other savings can ultimately cut the data center’s power-plant fuel by ~100-fold, with far lower capital cost.

Principle 13. Seek radical simplicity

Simple systems and components are easier to build, cheaper, use fewer parts, and have fewer failures and maintenance needs. Every part and system is a candidate for elimination. (Sandy Munro’s rule: any part that needn’t move and needn’t be of a basically different material shouldn’t be there.) A key path to simplicity is to use passive design and inherent control (homeostasis), using no energy or effort to maintain the desired state.

For example, start building design processes by asking: is there a sensible way to eliminate its HVAC equipment while providing comfort and health? If so, the saved capital cost can help achieve that elimination, often with money left over. U.S. space rockets separate their stages by explosive bolts activated by fancy control systems. But at least one Soviet space-rocket design simply set one stage atop another by gravity, secured by passive self-orienting cones and pins. When a stage ran out of fuel and stopped pushing, it would fall away as the next stage started up—no separation required.

The do-it-yourself Tvindkraft windmill built by teachers and townspeople in Ulfborg, Denmark, in 1975–78 had a capacity of 2 MW, decades before commercial units got that big. One of its ingeniously simple features was a safety system to stop the turbine if it started to vibrate too much. Governmentfunded turbines used elaborate computer/sensor controls, but the Tvind tinkerers reportedly just placed a big steel ball on a saucer up in the tower. If it shook too much, the ball would slop out of the saucer and fall down, and an attached string would pull a switch. It worked.

Principle 14. Tunnel through the cost barrier

Conventional designers invest in resource efficiency only until its gains no longer repay its costs. However, much larger savings can often be justified by other benefits. Such integrative design can even make very large savings cost less than small or no savings—creating expanding, not diminishing, returns to investments in efficiency.

For example, insulating a cold-climate house “too much”— about twice as much as its extra fuel savings could repay— also eliminated its heating system (furnace, fans, ducts, pipes, pumps, wires, controls, fuel-supply arrangements). This subtracted more capital cost than the extra efficiency added, so the ~99% saving in space heating energy reduced construction cost by about $1,100. This helped pay for saving ~99% of water-heating energy and ~90% of household electricity too, all with a ten-month payback using 1983 technologies. (Today’s are better.)

Principle 15. Wring multiple benefits from single expenditures

Each part, subsystem, or system should provide many benefits. Having each component perform just one function is a mark of dis-integrated design. Superlative integrative design can achieve a dozen or more functions per component, weaving an intricate web of enhanced value.

For example, a standard black-asphalt parking lot bakes in the sun. This shortens its life (by half for each 10 C˚ hotter), greets users with an unwelcome blast of radiant heat, cooks their cars (which become less efficient and more polluting when restarted while running an air conditioner big enough for an Atlanta house), bathes nearby buildings in superheated air (raising their costly air-conditioning loads), and soaks up light, so lawyers (fearful of assault lawsuits) demand such bright night-lighting that departing drivers are too dazzled to see, hence more likely to have accidents. Switching to light-colored pavement can make the paving material last indefinitely, create comfort for users, keep cars and buildings cool, reject enough solar heat to cool the Earth slightly (100 m2 of white surface is climatically equivalent to taking ~10 tonnes of CO2 out of the air), and so improve visibility that as little as 0.1 W/m2—just 2% of normal outdoor lighting power density—can suffice with new LED luminaires. Converting to those luminaires is also a cheap opportunity to add two-way charging stations for electrified cars, which can keep shoppers in the store longer. Making the new pavement pervious can even downsize or eliminate costly stormwater-management infrastructure

Principle 16. Meet minimized peak demand; optimize over integrated demand

Systems that meet varying demands (e.g., manufacturing processes and building ventilation systems) are typically designed to run most efficiently at peak demand, a condition that may be rare. This makes them less efficient and costlier to run under typically smaller, varying loads. In contrast, optimized systems are most efficient when integrated over the whole year’s diverse conditions, and are often downsized by special efforts to minimize or shift the peak demand that determines their capacity.

Often peak-capacity estimates are exaggerated by not delving deeply enough into the consequences of failing to meet a peak load, and by excessive design conservatism. One building owner saved much investment and energy by realizing that a bigger, more elaborate, and less efficient cooling system was simply not justified by the risk of modest overheating for just a few hours a year. Ceiling fans and natural ventilation could greatly extend the comfort conditions. ASHRAE standards even allow one-hour excursions from comfort conditions, because the human body takes that long to heat up and report discomfort! Careful attention to such details can often eliminate a heating or cooling system with little or no actual comfort consequence but big economic benefits. If in doubt, flexibility for minor fixes later can be designed in up front at little or no extra cost.

Principle 17. Include feedback in the design

Transform dumb systems into intelligent ones by monitoring and, when appropriate, graphically displaying their performance. This can inform optimal operation (a bad building well run usually outperforms a good building poorly run), drive continuous recommissioning, trigger timely maintenance, and yield a rich harvest of design lessons to improve the next design.

For example, displaying a big building’s real-time performance in 3-D color graphics often reveals undetected and unexpected behaviors. An observant designer can then detect incipient incorrect design assumptions, sensor calibrations, or equipment setpoints, test the adequacy of capacity (often avoiding unnecessary investments in more), improve operational practices, detect incipient failures before they occur, and find new opportunities both for retrofit and for smarter design next time. In contrast, in the 1990s hardly any chip fabs in the world could accurately measure how much energy they used to chill water: they didn’t even have a straight pipe run long enough for a properly installed flowmeter. Why not? Because they had been designed by “infectious repetitis” (i.e., copy the previous drawing), and the designers lacked any instruction, incentive, or intention to measure, learn, and improve.

RMI Rocky Mountain Institute © 2010

| Attachment | Size |

|---|---|

| 290.14 KB |