You are here

Fluid dynamics is crucial to a wide range of products and systems. Whether you’re designing an airplane, a refrigerator, a plumbing system, or a turbine, you can make it more energy efficient by optimizing fluid flow.

Fluid Dynamics Basics

Fluid Dynamics is a study of the motion of fluids, including both air and water. Engineers can create energy efficient designs that optimize fluid flow by making smarter choices on the form, speeds, and materials of their designs.

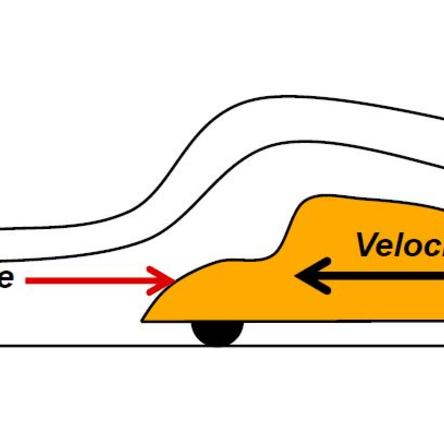

Energy is required to move objects through fluids, like air around a car. To improve aerodynamics and use less energy, you need to reduce the drag coefficient. For example, the Urbee car has enclosed wheel wells and gentle curves in the front and back. These give it a streamlined shape that reduces its drag coefficient to about half that of normal cars.

Energy is also lost when a fluid moves through an object, like water in a pipe or air through the ducts in a building. Major head losses occur from the friction forces between the pipe and the fluid, and minor head losses occur as the fluid travels through bends and valves. One way to optimize designs is to eliminate sharp turns or widen your pipes.

Simulating Fluid Flow

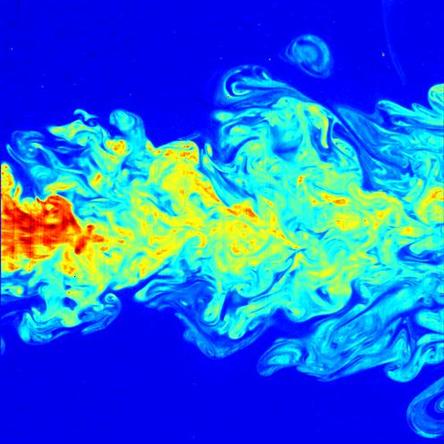

Computational fluid dynamics (CFD) simulations can help you optimize your designs by helping you to better understand how your design will interact with fluids.

Using Autodesk® Simulation Multiphysics or Simulation CFD you can perform CFD analysis and optimize the fluid flow of your design.

Simulation Resources

- Students and educators: Download Autodesk® Simulation Multiphysics software free of charge by visiting the Autodesk Education Community Download Center.

- Visit the Autodesk SIM Squad to explore the latest trends in simulation or connect with experts.

- Watch a 2-minute video that provides an Overview of Computational Fluid Dynamics (CFD) Simulation.

| Attachment | Size |

|---|---|

| 328.94 KB | |

| 7.14 MB | |

| 41.18 MB |