In their New Product Development class, a team of UC Berkeley graduate engineering students were challenged to develop a cost-competitive, environmentally friendly refrigerator. The Berkeley team was paired with a group of industrial designers from the Universidad Nacional Autónoma de México and Mabe, an Mexican appliance manufacturer.

Autodesk Software Used:

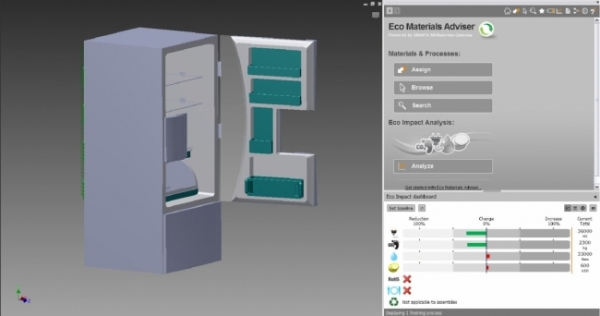

By analyzing the lifecyle environmental impacts with the Autodesk Eco Material Adviser, the team realized that reducing energy use was the most effective way to improve environmental performance.

But through user research, the team realized they needed to focus on user’s needs for economy, good aesthetics, and ease of use. To be a viable product in the Mexican market, it was especially important that any environmentally friendly technologies be affordable for both the company and the user.

The student’s final design features a quick access tray that allows people to access the food they use most without opening the full door and an insulated window that allows you to see inside the fridge. Its adjustable shelves and large vegetable tray also makes it easier to organize and access the food. All of this keeps the fridge closed longer, which saves energy by preventing the cold air from escaping.

To save more energy, the team also used innovative phase change material that acts as a thermal battery. By only running the compressor to “charge” the battery at night, when electricity rates are low and ambient temperatures can be cooler, the fridge can stay cold all day while saving money for the end-users. The team estimates that this design could reduce energy use by 40%.

To communicate their final design, the team created an interactive 3D model and animated exploded drawings using Autodesk Inventor Publisher (download it below).

Downloads:

- Inventor Publisher Dataset

- Energy Use Calculations & Assumptions (including homework questions)

- Eco Material Adviser report - Comparison of a fridge with and without a PCM cooling system. EMA was used to choose stainless steel for the PCM box and propylene glycol as the PCM. Energy assumptions as explained in the calculation document.

- Conclusions from testing a physical prototype

Additional Images (click for larger view)

Eco Materials Adviser

Energy Savings Strategy

Eco Fridge Features

Competetive Analysis

Energy Effectiveness

Phase Change Material (PCM)

Compressor Schedule

User Research

Initial Concept Sketches

Initial Concept Sketches

Initial Calculation and Sketches - PCM

Physical Prototype

Testing and Physical Prototype

Freezer at Bottom

Vegetable Compartment

Quick Access Drawer

Rendering of Final Fridge Design

| Attachment | Size |

|---|

| Attachment | Size |

|---|---|

| 2.17 MB | |

| 477.97 KB | |

| 227.34 KB | |

| 590.39 KB |