A single-material spool is up to 80% lighter compared to conventional spools. Designed to foldable, taking up less space, and can be easier to return to the supplier for reuse, or can be biodegraded.

Autodesk Software Used:

Challenge Summary

The goal of the Cradle to Cradle Design Challenge was to eliminate the concept of “waste” by designing products with materials that may be perpetually cycled to retain their value as nutrients to fuel growing global economies.

Design Summary & Considerations

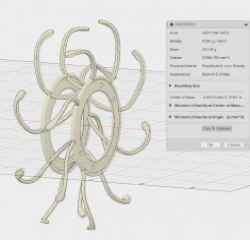

Most of the materials for low-budget and consumer-level 3D printers are supplied in form of polymer wire coiled on spools, which are heavy, bulky, and are rarely, if ever recycled. To address this issue, professional designer Bartlomiej Gaczorek developed Loop Supply Medusa Spool using Autodesk Fusion 360 demonstrating an innovative approach to using t-splines for the design, and simulation to assess the strengths of the overall model. Made from BASF's ecoflex®, the single-material spool is up to 80% lighter compared to conventional spools. The spool is also designed to foldable, thereby taking up less space, and can be easier to return to the supplier for reuse, or can be biodegraded.

Autodesk Fusion 360

Autodesk Fusion 360 was the main 3D software to create LOOP Supply Medusa spool concept. It covers all conceptual, modeling, simulation and visualization needs. Even Möbius strip used in the logo was modeled and rendered there.

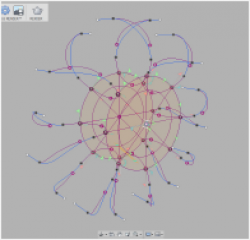

Even though the organic shape of the Madusa spool was achieved thanks to innovative T-spline pipe modelling tool, the design was parametric and incorporated motion study joints for simulate compressing and twisting. Bartlomiej created base "rig" and then 3 derivatives: unfold, half-folded and folded. In the last phase cobra-head endings were speed-modeled by hand.

This is the most efficient technique for designing organic shaped flexible parts. Fusion 360 allowed Bartlomiej to approximate spool weight what couldn't have been possible without costly prototyping. Easy to use rendering engine gave me a possibility to quickly and realistically visualize the product.

|

|